Operational Instruction / DE

4

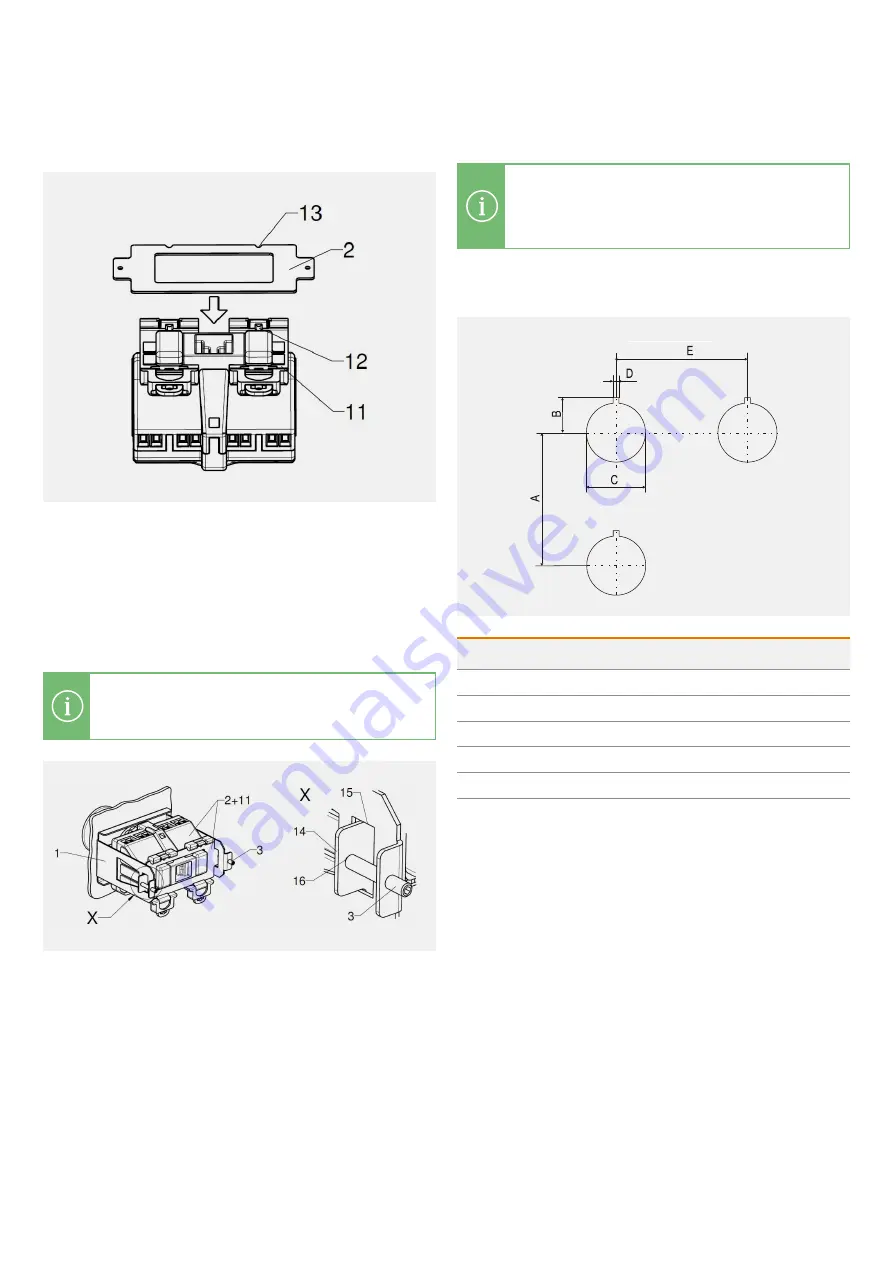

Screwing the mounting bracket to the base

NOTE

The position of the switch must correspond to that

of the actuating element.

–

Hang the switch (11) with latched base plate (2) in the

mounting bracket (1). Lugs (14) on the base plate (2) must

be placed in the side openings (15) of the mounting bracket

(1). To do this, gently prise the mounting bracket apart.

–

Screw the grub screws (3) with the tappets facing forwards

into the threaded holes on the mounting bracket. Grub

screw: Allen screw, width 1.5 (0.059). Centre the grub

screws in the drill holes (16) of the base plate (2) and tighten

slightly.

Installation and commissioning

NOTE

Detailed information on installation and

commissioning can be found in the operating

instructions for switch type 07-3381-...

Installation grid dimensions

Locking the base plate onto the switch

–

Place the base plate (2) onto the underneath of the switch

(11). Ensure that the openings in the base plate (13)

correspond to the retention lugs on the switch (12).

–

Press the base plate (2) to lock it into place.

mm

in

A

100

3.9

B

16,5

0.65

C

∅

30,3

+0,3

∅

1.9

+0,01

D

3

30

E

100

45