Product description

Ex p control unit

Motor Purge Controller

Page 20 of 96

01-37A2-7D0003_Operating instructions_MPC_20210923_0_en.docx

Rev. 0

3

Product description

3.1

General

The type of protection Ex p, called “pressurised enclosure”, is based on the

measure that explosive gases present in a closed volume are flushed out and

then an overpressure is generated and maintained in relation to the surrounding

atmosphere. Due to the higher pressure inside the housing compared to the

atmosphere, explosive gases cannot penetrate the inside of the housing at any

time. This creates an explosion-free area in which electrical devices can be

installed and operated, which are not themselves explosion-proof.

The APEX

mpc

or SILAS

mpc

control units described in these operating instructions

operate using the “pressurised enclosure with compensation of leakage losses”

technology. In detail, this refers to the maintaining of an overpressure in a

housing by supplying purging gas in order to compensate for any leakage losses

that occur in the housing.

The housing must be purged with purge gas prior to starting up, so that the

explosive atmosphere (gas) that has penetrated during downtime does not

become a hazard. The amount depends on the flow rate determined during the

initial start-up.

Since a safe state in the housing is only achieved at the beginning of the

operating phase, the Ex p control unit and its system components must be

designed to be explosion-proof.

3.2

Ex p control unit APEX

mpc

/ SILAS

mpc

The APEX

mpc

or SILAS

mpc

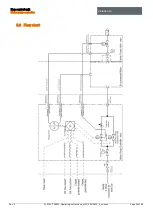

control unit with its system

components is an automatically operating control for

monitoring, controlling and regulating pressurised motors in

the hazardous areas of zone 1/21 or zone 2/22.

The Ex p control units are suitable for all common

applications in the pressurised enclosure of electric motors.

Each system structure consists of an Ex p control unit

APEX

mpc

or SILAS

mpc

and the associated pressure monitor mpv. The APEX

mpc

or

SILAS

mpc

control unit is intended for installation onto the pressurised motor and

the associated mpv at the purge air outlet point.

3.3

Pressure monitor, mpv

The pressure monitor mpv has two functions within the Ex p

control unit. First, it serves as a pressure relief valve, which

opens when the internal pressure is too high and reduces the

excess pressure. Second, an orifice is integrated in the

pressure monitor, via which the differential pressure is measured by means of

the sensor function unit.

In connection with the motor purge controller, this must be installed separately

on the pressurised motor. Furthermore, measuring hoses must be connected

between the pressure monitor and the sensor function unit.