사용설명서

Instructions for use

IU 17-438

Rev.

0

del

18.03.2019

pagina

9

di

17

이문서는

NUOVA ASP

의재산입니다

.

저작권은형태불문하고그전부또는일부에대해

NUOVA ASP

의사전승인을받아야합니다

.

The present document is property of NUOVA ASP. Its copyright in any format, whole or partial, must be before authorized by NUOVA ASP.

IU17-438_r0.doc

3.5

나사가공

3.5

Threading

나사산은치수및제조공차를고려하여다음표의항목중에서선택할수있습니다

.

The threading may be chosen between that indicated in the following tables, taking into

account dimensions and tolerances of manufacturing.

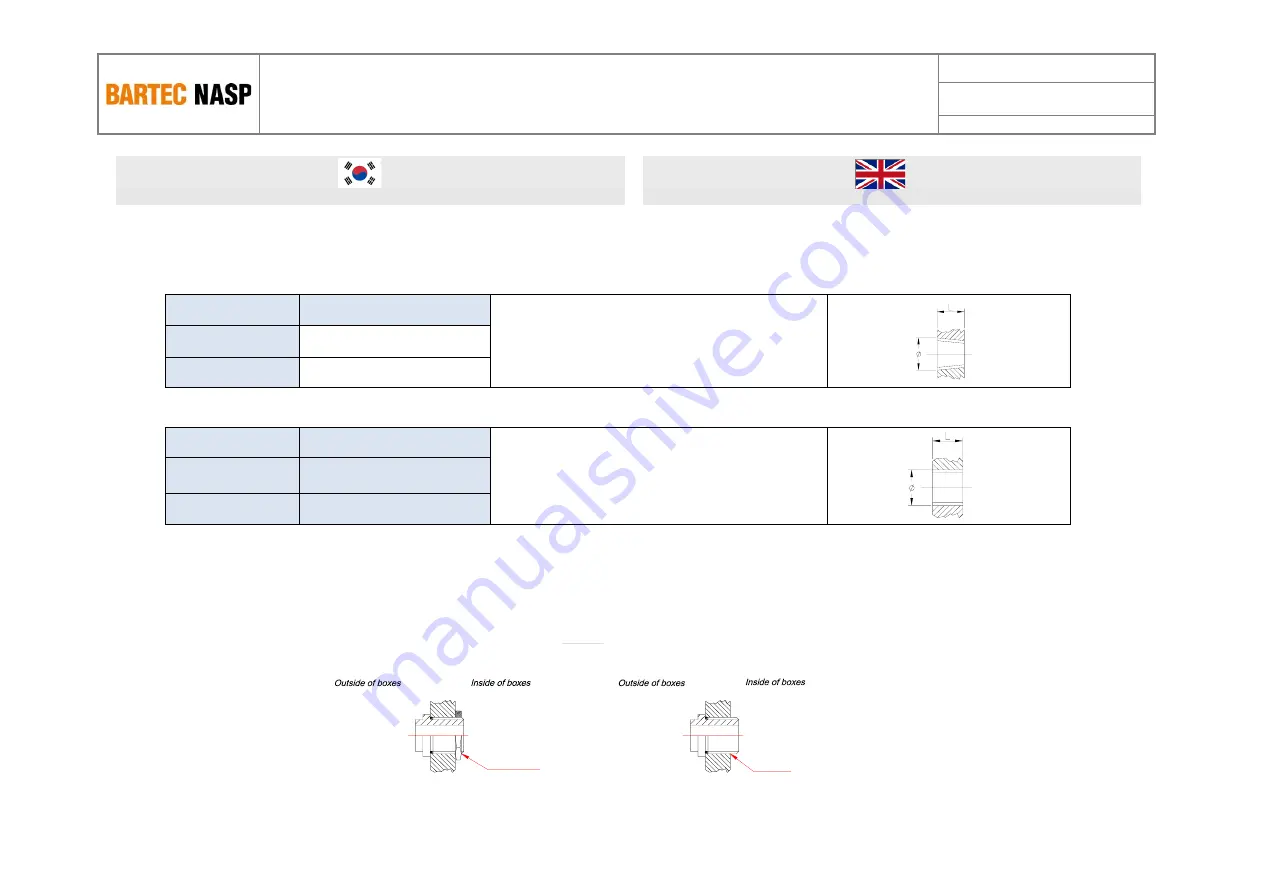

원추형나사산

Conical threading

크기

Ø

Size Ø

참조표준

Standard of reference

최소맞물림나사산의수

5

Min. number of threads engaged

5

Rc 1/8”÷4”

EN 10226-2

(only ATEX)

NPT 1/8”÷4”

ANSI/ASME B1.20.1

원통형나사산

Cylindrical threading

크기

Ø

Size Ø

참조표준

Standard of reference

최소맞물림나사산의수

5

Min. number of threads engaged

5

G 1/8”÷4”

ISO 228/1

M6÷115 x p

ISO 261

원통형나사산은

ISO 965/1

및

ISO 965/III

표에명시된것과동등한가공공차를가져야합니다

(

정합공차

6H/6g.

원통형나사산의경우느슨해지지않도록잠금장치를제공해야합니다

(

기계식잠금

, LOCTITE

씰또는동등품

).

The cylindrical threading must have manufacturing tolerances equivalent to those in tables

ISO 965/1 and ISO 965/III (matching tolerance 6H/6g.

For the cylindrical threading must be predict an anti-loosing grip device (mechanical block,

LOCTITE seal or equivalent).

최대길이

200mm,

최대직경

3”

의도관튜브

(UNI 7683:1977)

를설치하는것도가능합니다

.

It is possible to install a conduit tube (UNI 7683:1977) with maximum length of 200mm and

maximum diameter

3”.

ESTERNO CUSTODIA

INTERNO CUSTODIA

FIG. 2

ESTERNO CUSTODIA

INTERNO CUSTODIA

controdado

locknut

LOCTITE

박스외부

박스외부

박스내부

박스내부

잠금너트