Ex p Control Unit

SIEMENS Set

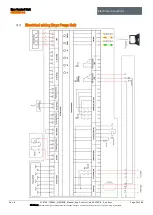

Electrical connections

Rev. 0

01-37A2-7D0004_SIEMENS_Manual_Exp-Control-Unit_20220216_0_en.docx

Page 31 of 80

Disclaimer: We reserve the right to make technical changes. Changes, errors and printing errors do not justify claims for damages.

General

Connection notes

DANGER

DEATH OR SERIOUS PHYSICAL INJURY WHEN THE COVER OF THE CONTROL

UNIT APEX IS OPENED IN AN EXPLOSIVE ATMOSPHERE.

Risk of explosion.

Before opening the lid of the enclosure, check the atmosphere for

any explosive gases.

ATTENTION

SHORT-CIRCUITS DUE TO LOOSE OR PROTRUDING WIRES IN THE CONTROL

UNIT APEX.

The control unit APEX may be damaged.

All core wires, including those not required, must be attached to a

terminal.

Lay the wires only in the space between the shield bus and the

connecting terminal.

Make sure that none of the wires are loose or jump out/protrude.

AVOID DAMAGE TO THE SEAL.

Cancellation of the Ex protection concept.

Visual inspection of the seal when closing the control unit APEX

(cleanliness, seat and integrity).

AVOID RAPID DISCONNECTION AND RECONNECTION OF THE POWER

SUPPLY.

Internal protection circuits can trip

Wait approx. 30 seconds between switching off and switching on

again.

Recommendation for the securing of active parts

The Ex e terminals should be protected against contact by a

protective cover.

The procedure for connecting cables to the Ex p control unit is described in the

following:

Procedure:

Establish the electrical connections in accordance with the terminal

assignment. Terminals are designed in tension spring technology. A

suitable tool must be used for this purpose.