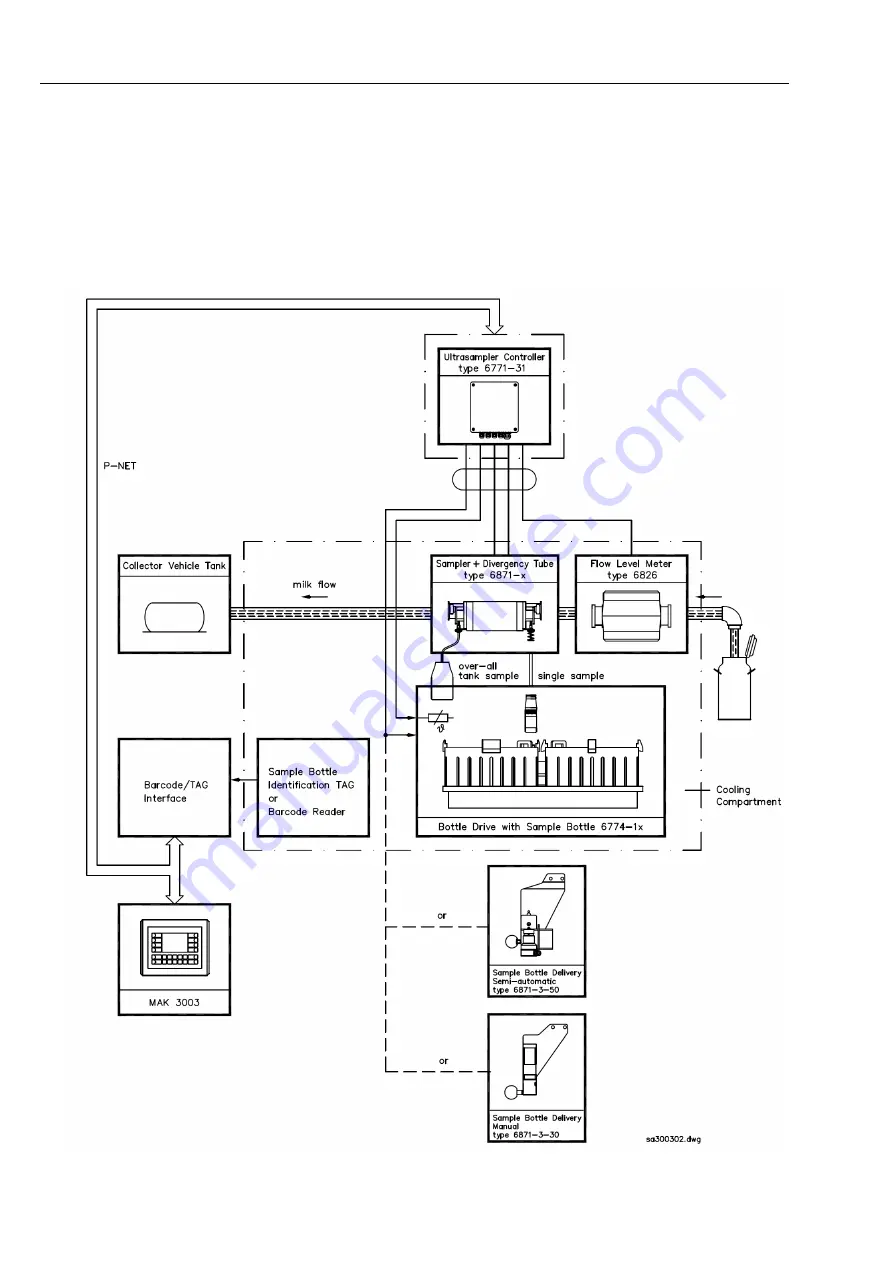

ULTRASAMPLER® sample collection system

150

Measuring System MAK TIGER 3003 Service manual, SA 131128, 10.03.2020

MAK 3003 matches the milk sample to the milk producer on the basis of the

bar code or TAG, thereby ensuring that the data will be correctly attributed

for the subsequent laboratory analysis.

Fig. 2 illustrates the flow of the data signals and control signals between the

functional units of the ULTRASAMPLER and MAK 3003.