ASSEMBLY and OPERATION

4

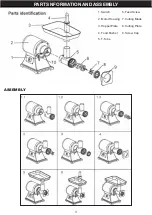

1. Assemble the head part in the motor housing and lock it. Place feed screw into the head, login

first by turning the feed screw slightly until it is set into the motor.

2. Place the cutting blade onto the feed screw shaft with the blade facing the front as illustrated. If

it is not fitted properly, meat will not be ground.

3. Place the cutting plate next to the cutting blade, the gap aligns the pin to the head.

4. Screw the cap into place until it is tight. Place the hopper plate on the machine.

DO NOT over tighten, Place the hopper plate on the head and fix it into position. Locate the

unit on a firm place.

The air passage at the bottom and the side of the motor housing should be kept free and not

blocked. Cut all food into pieces that will fit in the hopper. Plug in the grinder and switch the

power to ON.

5. Feed food into the hopper plate and use the pusher to guide meat into the hopper. After you are

finished grinding all the meat, switch the power OFF and unplug the grinder.

NOTE: If minced meat is not discharged smoothly or in the form of a paste, the causes and remedy

could be:

1. Screw cap is too tight making it so the cutting blade does not make proper contact with the

cutting plate. Readjust to fit.

2. The cutting plate is blocked and needs to be cleaned.

3. The cutting blade edges are dull, grind or replace it.

JAMMING: When the motor is locked or when the motor continues to function but no meat is coming

out of the cutting plate. This could be due to bone or other materials jamming the hopper.

Switch off the power to the grinder and turn the switch to REVERSE to clear the materials .

CLEANING THE GRINDER

DISASSEMBLY: Make sure the power is switched OFF and the motor has stopped completely.

Disconnect the plug from the power outlet. Unscrew the cap sides and locking knob. Take out the

head (with cutting plate, cutting blade and feed screw), then put head mouth downward in order

to take out the cutting plate, cutting blade and feed screw.

CLEANING: Remove meat etc. wash each part with warm soapy water.

A bleaching solution containing chlorine will discolor aluminium surfaces.

DO NOT immerse in motor housing in water, but only wipe it with a damp cloth.

Thinners and benzenes will crack or change the color of the unit.

A little salad oil on part 6-8 after washing and drying will help lubricate the unit.

NOTE: Use extreme caution when handling the cutting blade.

NOTE: DO NOT use a perforated disc with holes >8mm in diameter or smaller unless an additional

protected hood is provided at the discharge outlet.