9

RECOMMENDED GROUNDING METHOD

IMPORTANT

: Be sure to use the new hose-sets supplied with the appliance to connect to water mains and

that old hose-sets should not be reused.

1.

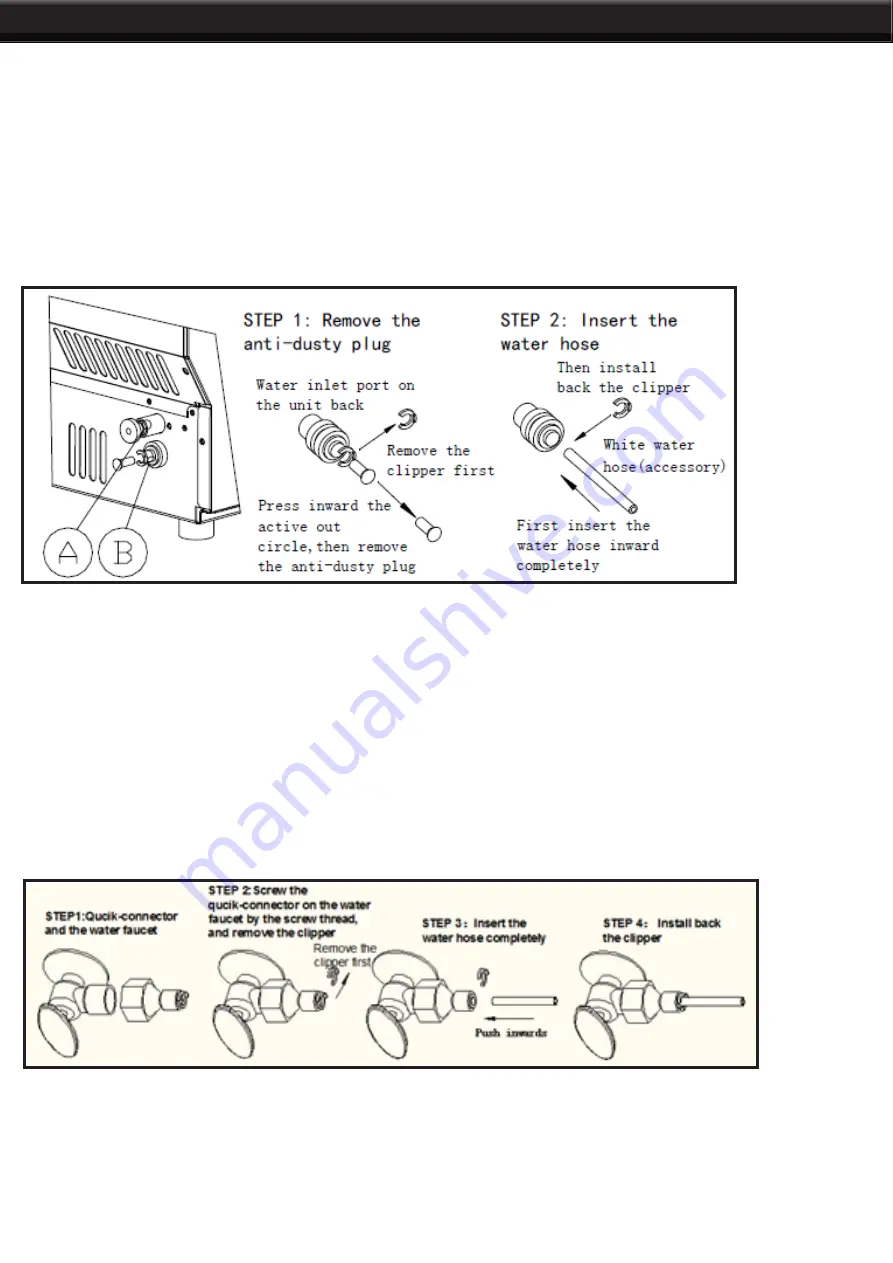

Connect the water supplying hose to the unit (For automatic water supplying).

Step 1:

First remove the

clipper on the water inlet port for main water supplying (indicated in the following illustration “B”) located at

unit back, then pushing inwards the anti-dusty plug, use your other hand’s finger to press the out circle to

fix the anti-dusty plug, then take down the anti-dusty plug; Step 2: Insert the one end of the white water

supplying hose into the water inlet port, and push inward completely, and install back the clipper, then water

supplying hose connection is completed.

2. CONNECTING THE WATER DRAINAGE PIPE

: Pull out the water drainage cap with black color (indicated

in above illustration), then connect the white drainage pipe included in accessory, again connect the other

end of this drainage to the main water drainage pipeline. Make sure not to set the drainage pipe too high.

3.

Connect the water hose to the water faucet of the water main supply system (For automatic water

supplying). First, install the supplied water quick-connector(from 1/4 to 1/2 inch, with black sealing circle)

to the water faucet by screw thread; Second, remove the clipper from the water quick-connector, insert the

another end of the water hose into this quick-connector port completely, then install back the clipper, also

this step is completed. Note: The water faucet should be supplied by the customer himself.

IMPORTANT

: The water pressure of main water supply system must be 0.04-05 MPa at least and 0.6

Mpa at largest. If the pressure is too big (like bigger than 0.8 Mpa), it should be installed with pressure

decreasing valve first.

NOTE

: If you set the unit supplied by manual water filling, don’t need to do step 1 and 3. If you choose

the automatic water supplying, the ice maker requires a continuous water supply with pressure 1-6 Bar as

required in above specification table.

OPERATION