13

INTERIOR CLEANING

FOR ICE STORAGE BIN

The ice storage bin should be sanitized occasionally. Clean the bin before the ice maker is used for the first

time and reused after stopping for an extended period of time. It is usually convenient to sanitize the bin

after the ice making system has been cleaned, and the storage bin is empty.

1.

Disconnect power to the unit.

2.

Open the door and with a clean cloth, wipe down the interior with a sanitizing solution made of 28g of

household bleach or chlorine and 7.5L of hot water (95 °F to 115 °F).

3.

Rinse thoroughly with clear water. The waste water will be drained out through the drain pipe.

4.

Reconnect power to the unit.

The ice scoop should be washed regularly. Wash it just like any other food container.

NEVER

use solvent cleaning agents or abrasives on the interior. These cleaners may transmit a poor taste

to the ice cubes or damage the interior of the machine.

ICE MAKING PARTS CLEANING

During the using, periodically to clean these main system of your ice-maker. During the using,

periodically to clean these main system of your ice-maker.

1.

Repeat above step to clean the water tank and other inner parts of the unit.

2.

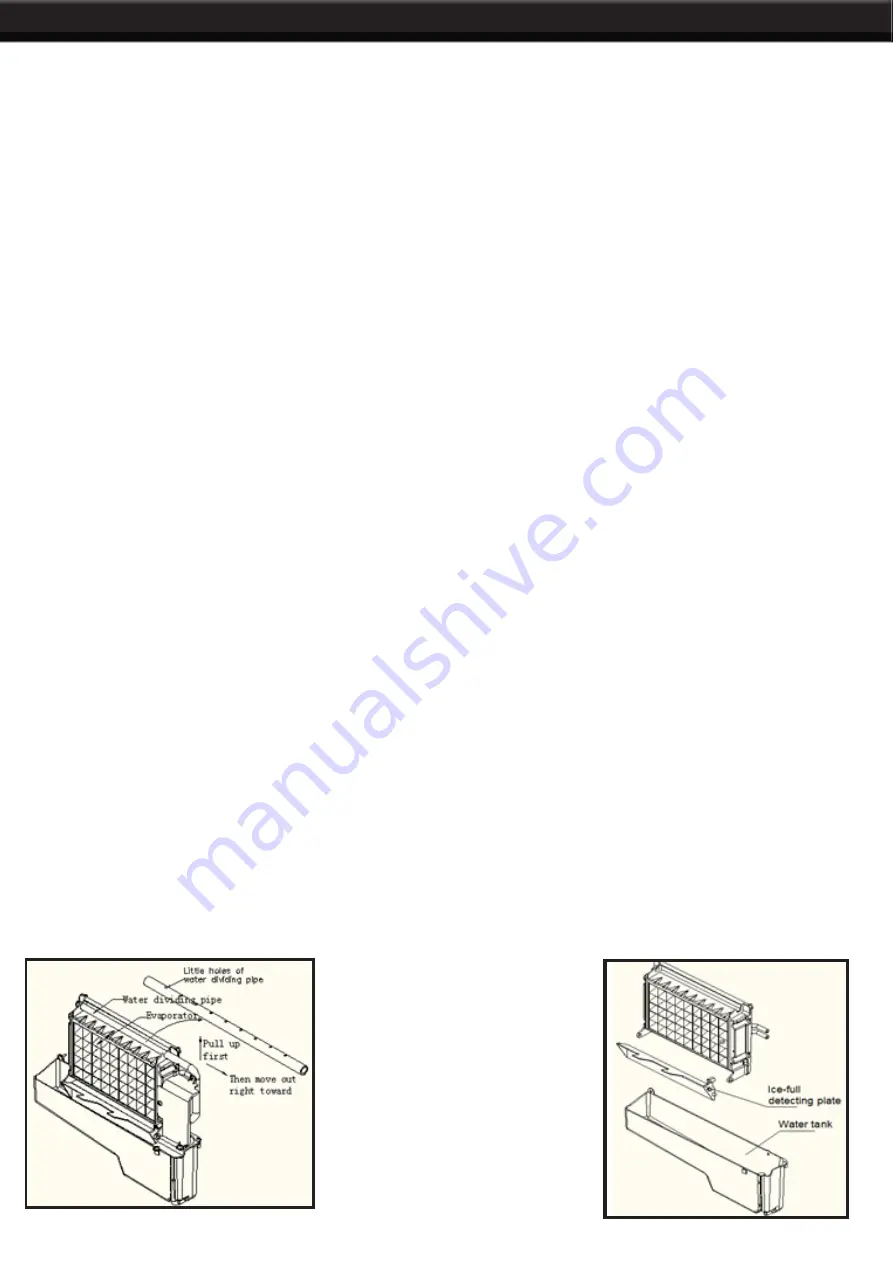

Especially, to the water dividing pipe on the evaporator, when the compressor and the water pump run

normally, but if there is no water flowing out from the water dividing pipe or the water flowing is very small,

please discharge this water dividing pipe to clean carefully. Clean each little holes on the water dividing

pipe displayed in the following illustration, make sure each hole is not clogged by something, then install

back to the original location.

3.

The length of cleaning period is related to your water quality. And drain the water more frequently, the

unit and its water pump can work much longer.

4.

When there are ice cubes on the surface of the evaporator, but can’t fall off easily, do not use the

mechanical substance to remove it by force; Only press the “ON/FF” button for more than 5 seconds, the

unit will enter the ice melting process, after some while, the big ice-cubes will fall down, then turn off the

unit and unplug the power cord to clean the surface of the evaporator.

5

. For the water tank and ice-full detecting plate

Also the water tank and the ice-full detecting plate is very important to keep your ice cube hygienic. Put

mixture of neutral cleaner & water into a clean water jet, then spray to all the inner surface of tank & the ice

detecting plate. Wipe these surfaces as far as possible with a clean cloth. And then, spray the surfaces with

clean water, wiping with a dry clean cloth. Then drain out the cleaned water in the water tank by pulling out

the Water drain pipe of the water tank indicating “H” in above illustration. When all of the cleaned water has

been drained out, to install back the water drain pipe of the water tank.

MAINTENANCE