SUGGESTION

: After cleaning the interior parts and install back to its respective position, and return

machine to work, discard first batch of ice.

SYSTEM CLEANING USING NU-CALGON NICKLE SAFE ICE-MACHINE CLEANER

Minerals that are removed from water during the freezing cycle will eventually form a hard scaly deposit in

the water system. Cleaning the system regularly helps remove the mineral scale buildup. How often you

need to clean the system depends upon how hard your water is. With hard water of 4 to 5 grains/liter, you

may need to clean the system as often as every 6 months.

1.

Turn off the ice maker. Keep the ice maker connect to the main water supply and drainpipe. But shut off

the water faucet of main water supply.

2.

Open the door and scoop out all of the ice cubes. Either discard them or save them in an ice chest or

cooler.

3.

Making the cleaning solution. Please mix the Nu-Calgon Nickle Safe Ice Machine Cleaner with water to

make the cleaning solution. Use a plastic or stainless container with more than 4 liters capacity, mix 300 ml

Nu-Calgon Nickle Safe Ice-machine Cleaner with 2.8 liters warm water about 120 °F-140 °F, Then divide

them for 2 shares equally in 2 cups. It is better to keep the temperature of each cup of the cleaning solution.

4.

Check to be sure that the water drain pipe of the water tank has been installed properly in the slot of the

tank wall. Then Pour one cup of Nickel-Safe Ice Maker Cleaning Solution into the water tank. Wait about

for 5 minutes.

5. Turn on the power to the ice maker, then press “TIMER/ CLEAN”button on control panel for more than

5 seconds, to enter the self-Cleaning program. Same as above explanation, the water pump runs for 8

minutes and stops for 3 minutes, one cycle, again one cycle. The total duration time is 20 minutes for one

self-cleaning program. During this process, the TIMER symbol will always be on during this period, and the

digit window will indicate the time left.

6

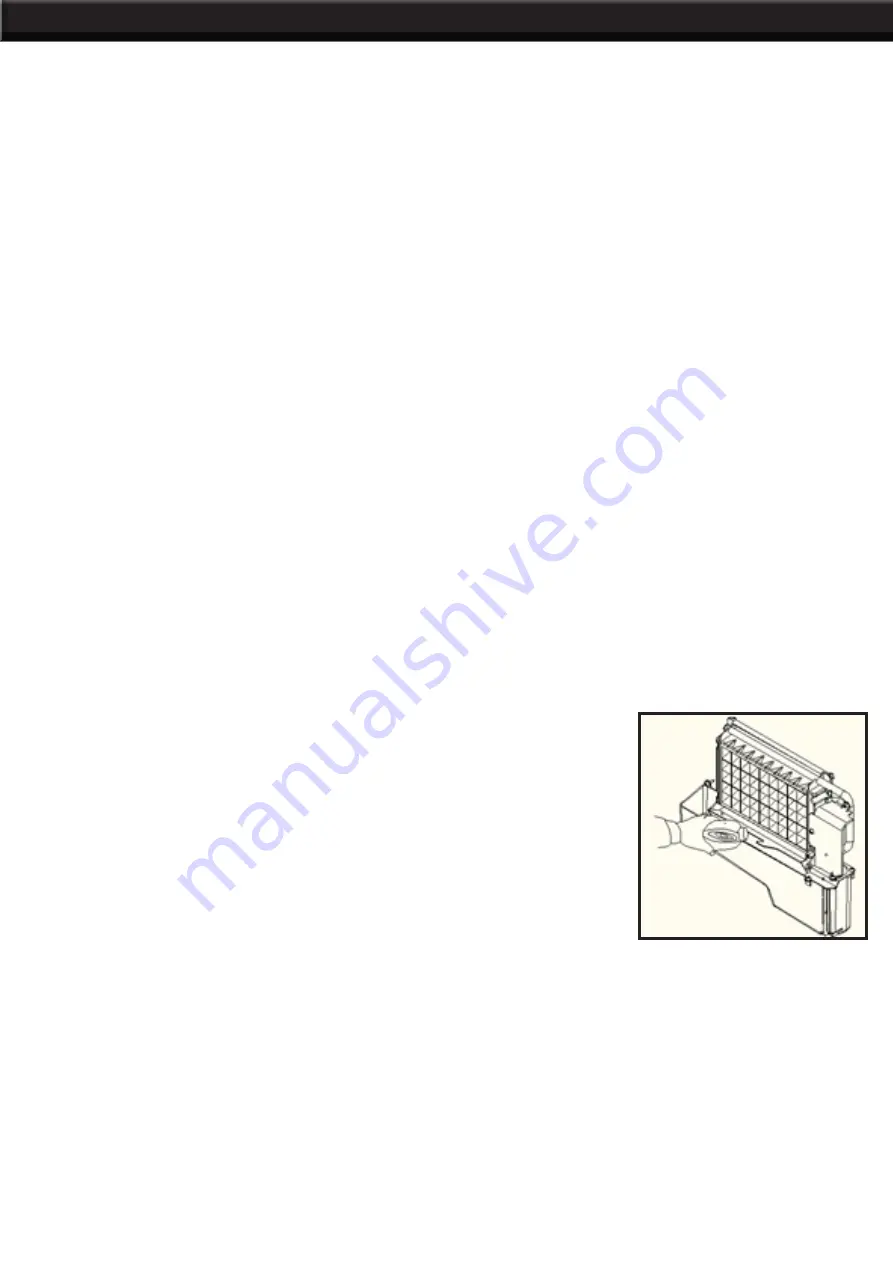

. After 20 minutes of one self-cleaning program completing, pull out the drain pipe of the water tank, drain

the cleaning solution down to the lower ice storage bin. Shake the unit slightly to drain out all of the cleaning

solution completely. Then install back the drain pipe to the slot of the water tank.

7.

Repeat steps 4--6 to clean the ice making assembly system again.

8.

Then open the water faucet of the main water supply, Let the water flow in

the unit. And press the TIMER/CLEAN button on control panel for more than

5 seconds, to enter the self-Cleaning program. Same as above explanation,

the water pump runs for 8 minutes and stops for 3 minutes, one cycle,

again one cycle. The total duration time is 20 minutes for one self-cleaning

program. During this process, the Timer symbol will always be on during this

period, and the digit window will indicate the left time. Through this process,

It will rinse the water dividing pipe, evaporator, water pump, silicone pipe,

and water tank, etc..

14

9.

After one self-cleaning program complete, then pull out the drain pipe of the water tank, drain the

cleaning solution down to the lower ice storage bin, also shake the unit slightly to drain out all of the water

completely. Then install back the drain pipe to the water tank slot tightly.

10.

Repeat the step 8-9 again for 2 times.

11.

Following the above program to clean the ice storage bin .

12.

Then this special cleaning program finish, you can return to the regular ice making mode. And suggest

to discard the first batch of ice cube.

MAINTENANCE