Pag. 11

- Unscrew screwed-on cap (Ref. 1), remove the

nozzle (Ref. 2) and replace it with one that is

suitable for the type of selected gas.

- Refit the screwed-on cap (Ref. 1).

- Use a foam product to check that the cap does

not leak.

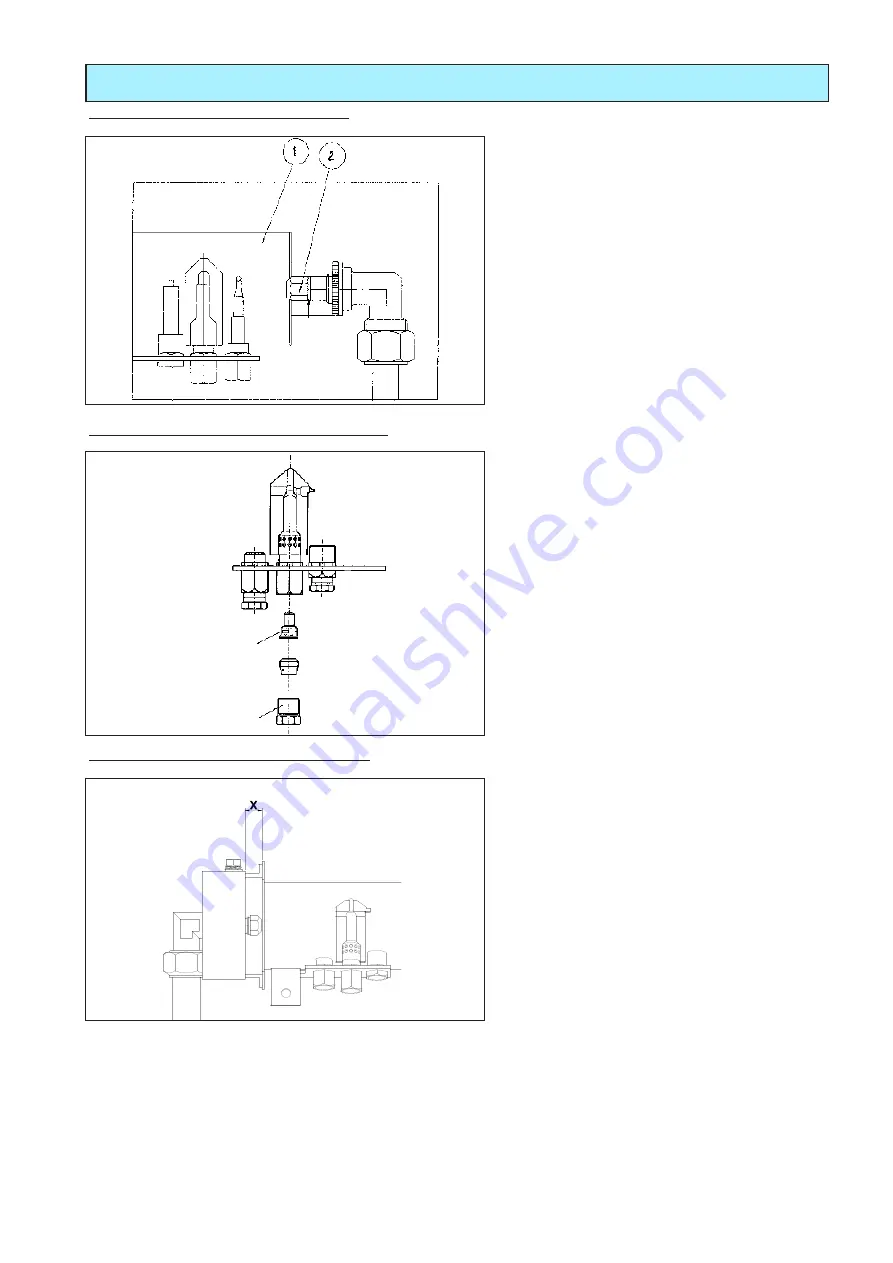

REPLACING THE PILOT BURNER NOZZLE (Fig. 5)

WARNING! After each conversion to a different gas type make sure you:

- Fix an indelible sticker on the rating plate giving the data relative to the new installation.

- Test for leaks on the gas circuit.

Before delivering the appliance to the user:

- check that it operates correctly,

- instruct the user on how to use it.

Fig. 5

1.5 CONNECTING TO A DIFFERENT TYPE OF GAS

REPLACING MAIN BURNER NOZZLE (Fig. 4)

1

Burner

2 Nozzle

- Before adapting to a new type of gas, shut off

the gas cock upstream.

- Loosen the screws that hold the front control

panel in place and disconnect the electric

cables of the piezoelectric ignition.

- Loosen the main injectors (Ref. 2) and repla

-

ce them with those corresponding to the gas

used. The diameter is stamped in hundredths

of a millimetre on them and can also be che-

cked on the Specifications Table.

Fig. 4

ADJUSTING BRIDGE TO MAIN BURNER (Fig. 6)

- Unscrew the bolt that fixes the bridge .

- Position the bush at distance X = 4mm.

- Tighten the fixing bolt again .

Fig. 6