Pag. 13

3.2 SPECIAL MAINTENANCE

At regular intervals (at least once a year or more often in cases of frequent use), service the appliance thoroughly.

This includes checking the gas circuit, checking parts for damage and if necessary lubricating the taps if they are

difficult to use. Contact a specialised and experienced technician. A maintenance contract should be taken out

with a centre approved by the company.

3.3 CONTROL AND SAFETY DEVICES

If the appliance is not used for a long time or if it does not work or works irregularly, the gas stopcock upstream

of the appliance must be shut off.

All the parts of the appliance that are subject to wear can easily be accessed from the front of the appliance after

removing the front.

All the couplings use a dado and bicono, so great care must be taken in handling these components. If the part

is damaged during dismantling or reassembly it must be replaced with a new one.

of the appliance. Use warm soapy water on steel surfaces and then rinse in plenty of water and dry with a soft

cloth. Maintain the shine by regular polishing with a normal liquid polish.

Do not wash the work top or floor with

hydrochloric acid.

PLATE

In order to remove any encrusted residue, scrape with a hard plastic spatula positioned at an angle. Clean the

plate regularly using a damp cloth. After cleaning, switch the plate on for a few minutes at the maximun setting in

order to dry it as quickly as possible. Allow the plate to cool and apply a thin layer of vaseline oil.

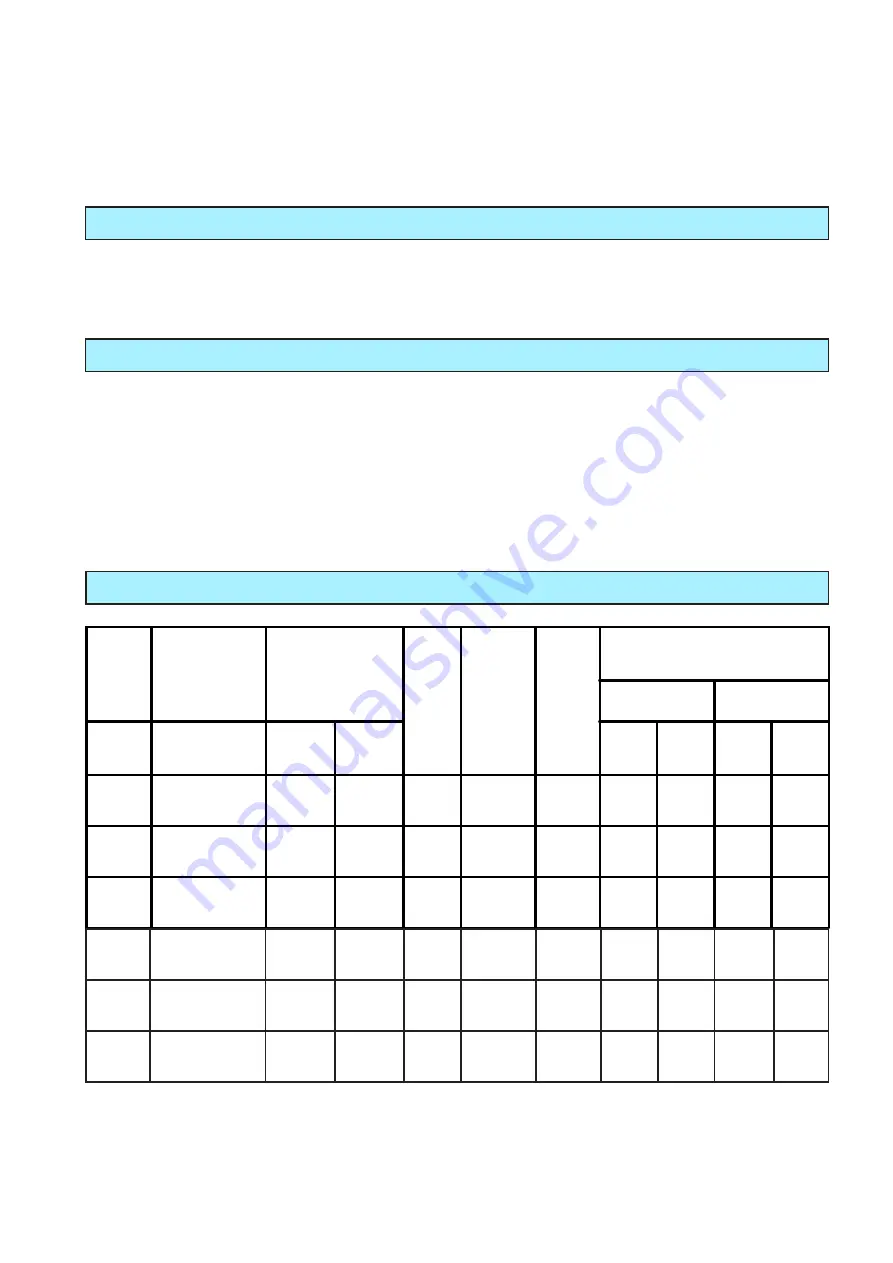

SPECIFICATIONS TABLE FOR GAS FRY TOP, CATEGORY II2H3+

Mod.

Rated

Output

Consumption Max

Type

Air

for

combustion

m3

Burners

Pressure in mbar

G30/G31=30/37mbar

G20=20mbar

Nozzles

Main burner

Nozzles

Pilot burner

kW (P.C.T.)

G30

G31

kg/h

G20

m3/h

G30

G31

mm

G20

mm

G30

G31

NR.

G20

NR.

FTG46...

4,6

0,35

0,48

A1

10

1

1,10R

1,60R

0,22

0,27

FTG66...

7,6

0,59

0,80

A1

15,5

2

1,00R

1,45R

0,22

0,27

FTG100

13,8

1,07

0,70

A1

27,6

3

1,60R

1,10R

0,22

0,27

LGG49..

4,6

0,35

0,48

A1

10

1

1,10R

1,60R

0,22

0,27

LGG69..

7,6

0,59

0,80

A1

15,5

2

1,00R

1,45R

0,22

0,27

LG6960

13,8

1,07

0,70

A1

27,6

3

1,60R

1,10R

0,22

0,27