- 37 -

Button lock / unlock

Keypad lock:

1. Make sure no procedure is in progress.

2. Do not key in anything for 30 seconds; the display shows

“Loc”

message

for 1 second and the keypad will be locked automatically.

To unblock the keypad:

1. Press and hold the button for 1 second: the display shows

“UnL”

message

for 1 second.

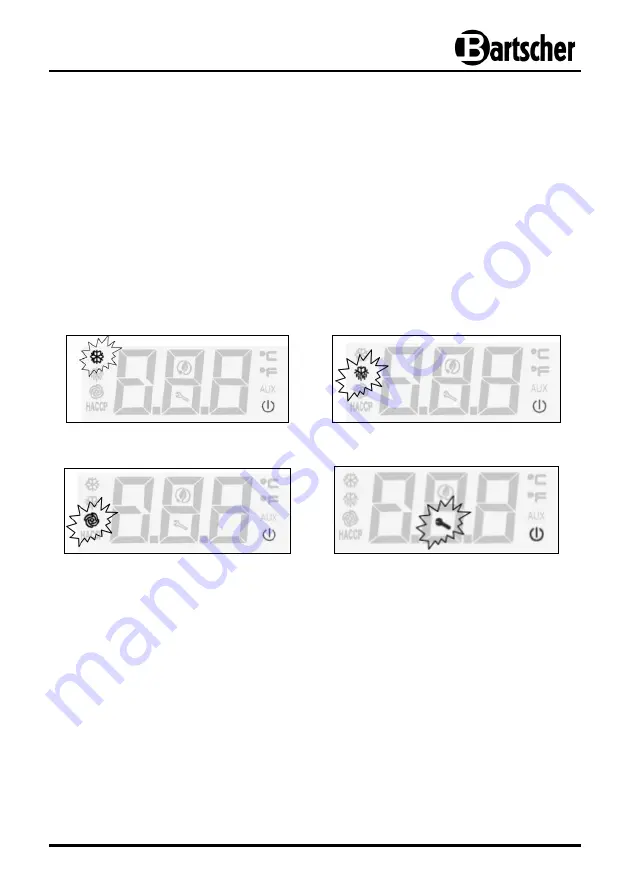

LED light indications

This LED light shows the status

(on or off) of the COMPRESSOR

This LED light shows that defrosting

is in progress

This LED light shows the status

(on or off) of the BLOWER

When this LED light is on, it is

necessary to clean the condenser fliter