I.

SAFETY HI TEMPERATURE THERMOSTAT

Located in the control box it is a manual reset

switch that trips OFF the operation of the machine

when its bulb (located on the liquid line just

before the drier) reaches the temperature of

70

°

C (158

°

F).

J.

CLEANING SWITCH

(only SCE 20 - 30 - 40 - 50)

Located on the bottom left side of the control box

is used to energize the water inlet and the hot gas

valves so to charge the water into the sump tank

of the machine.

K. HI PRESSURE CONTROL (Water cooled

version)

Used only on SCE 20 - 30 - 40 - 50 - 65 water

cooled versions it operates to keep between

two preset values the hi-side or discharge

pressure of the refrigerant system by energizing

the coil of the water inlet solenoid valve that

control the cooling water flow to the

condenser.

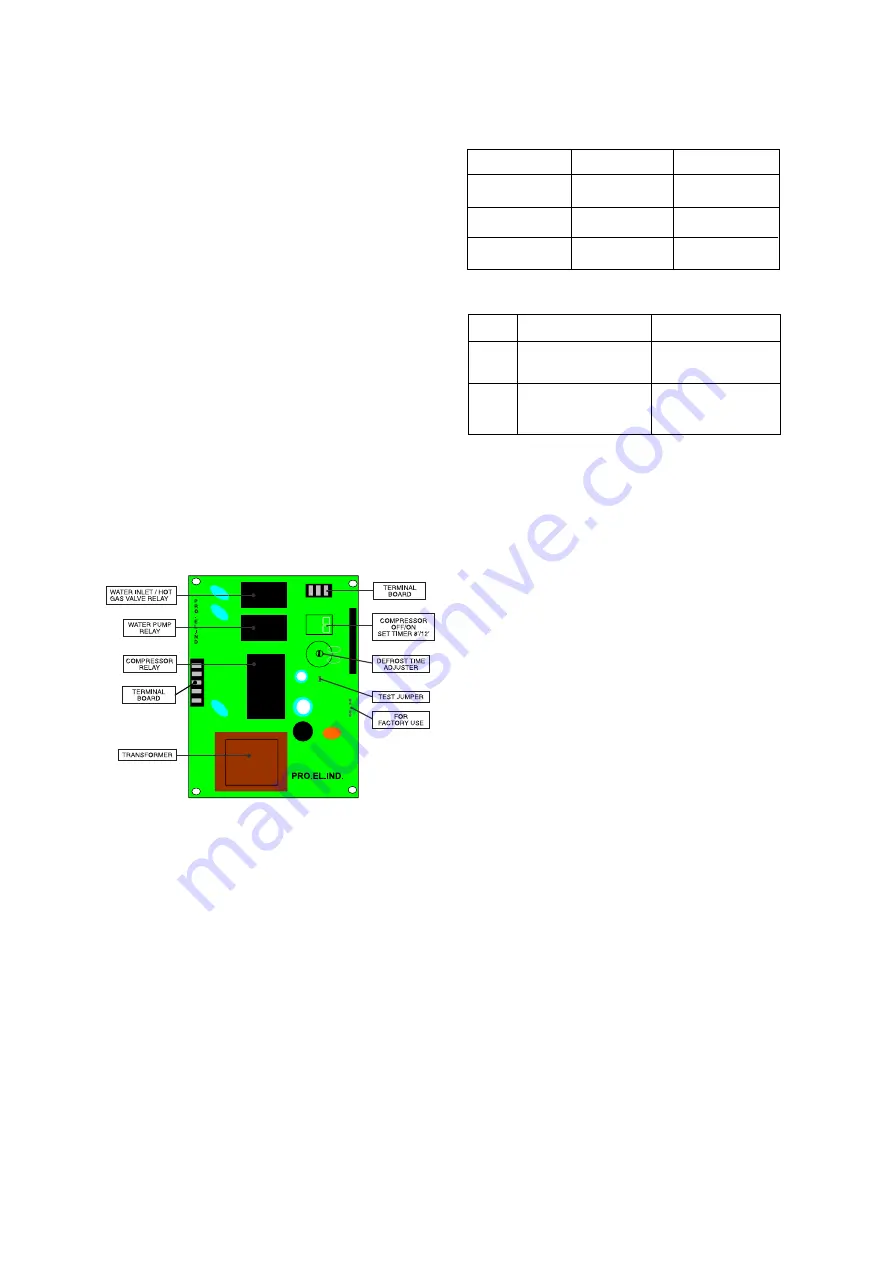

L. ELECTRONIC TIMER

(SCE 65 - 90 - 105)

Equipped with a Two Keys Dip Switch and one

Potentiometer, it manage the length of second

fase of the freezing cycle and the entire defrost/

harvest cycle with a factory pre-set times .

The first key (1) replaces the “Compressor Switch”

used on the previous electro-mechanical version;

factory setting is ON position to energize the

compressor during the standard operation of the

ice machine.

The same key (1) is switched to OFF position

when the cleaning cycle is required keeping the

water pump only in operation.

The second key (2) allows the setting of the timed

portion (Ta) of the freezing cycle according to the

model of the ice machine.

Dip Switch factory setting combinations

N. 1

N. 2

SCE 65

ON

ON

SCE 90

ON

ON

SCE 105

ON

ON

Resuming Chart with Keys 1 & 2 functions

N. 1

N. 2

ON

Standard Setting

Compressor ON

OFF

Cleaning Mode

Compressor OFF

The potentiometer is used to adjust the defrost

time and it is set directly from the factory according

to the model of the ice machine.

It can be adjustable from a minimum defrost time

of 60" (turn clockwise), to a maximum of 180"

(turn counterclockwise).

M. MASTER SWITCH

(only SCE 65 - 90 - 105)

Fitted in the control box the master switch has to

be used to start-up and to stop the ice maker

operation.

N. COMPRESSOR SWITCH

(only SCE 65 - 90 - 105)

Located in the control box is used to de-energized

the compressor during the cleaning.

O. FAN PRESSURE CONTROL

(only SCE 65 - 90 - 105)

Used on air cooled ice makers to maintain the

head pressure within the preset values.

P. WATER REGULATING VALVE

(only SCE 90 - 105 Water cooled

version only)

This valve controls the head pressure in the

refrigerant system by regulating the flow of water

going to the condenser.

As pressure increases, the water regulating val-

ve opens to increase the flow of cooling water.

Ta = 12'

Ta = 8'

13