USE AND MAINTENANCE MANUAL

2-Speed Gearboxes Series CE

M

.CE.GEN.ENG.DOCX

Issued

2018

Rev.03

Page 4 / 59

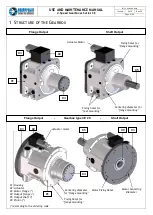

1 Structure of the Gearbox ___________________________________________________ 6

1.1 Delivery conditions _________________________________________________________________ 7

1.2 Data label ________________________________________________________________________ 8

1.3 Handling and lifting the Gearboxes ___________________________________________________ 9

1.4 Technical data ___________________________________________________________________ 10

1.5 Ordering code ____________________________________________________________________ 12

1.6 Motor flange dimensions ___________________________________________________________ 13

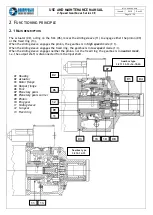

2 Functioning principle _____________________________________________________ 14

2.1 Main description __________________________________________________________________ 14

2.2.1 Gearbox in high speed mode (1:1) _______________________________________________ 15

2.2.2 Gearbox in low speed mode (1:i) ________________________________________________ 15

2.2.3 Gearbox in neutral mode ______________________________________________________ 15

2.2 General operating rules ____________________________________________________________ 16

3 Gearbox start-up _________________________________________________________ 17

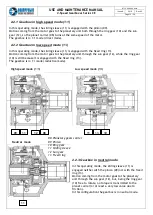

3.1 Motor specifications _______________________________________________________________ 17

3.1.1 Dimensions and tolerances _____________________________________________________ 17

3.1.2 Motor balancing ______________________________________________________________ 17

3.1.3 Matching motor - gearbox balancing _____________________________________________ 18

3.1.4 Screws tightening torque ______________________________________________________ 18

3.2 Assembling the motor on the gearbox - Gearbox CE 11 - 13 - 13+ - 16 - 18 - 20 _____________ 19

3.2.1 Motor shaft with key __________________________________________________________ 19

3.2.2 Motor shaft without key (straight shaft) - conical clamping unit ______________________ 20

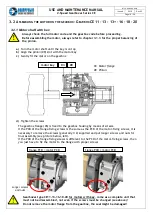

3.2.3 Disassembling the clamping unit (100) from motor shaft ____________________________ 23

3. 3 Assembling the motor on the gearbox - Gearbox type CE 12 - 14 - 15 _____________________ 24

3.3.1 Motor shaft with key __________________________________________________________ 24

3.3.2 Motor shaft without key (straight shaft) - conical clamping unit ______________________ 26

3.3.4 Assembling the gearbox on the motor ____________________________________________ 27

3.4 Motor-gearbox assembling options ___________________________________________________ 28

3.5 Gearbox Output __________________________________________________________________ 29

3.5.1 Verifying gearbox output loading capacity ________________________________________ 29

3.5.2 Gearbox output bearings: position and loading capacity ____________________________ 30

4 Assembling positions and lubrication _______________________________________ 31

4.1 Choosing the lubrication mode ______________________________________________________ 31

4.2 Splash Lubrication ________________________________________________________________ 32

4.2.1 Monitoring the oil level: Oil Sight-glass and Oil Level Sensor _________________________ 32

4.3 Oil Recirculating Lubrication (Forced Lubrication) _____________________________________ 34

4.3.1 Monitoring the oil flow: Oil Flow Rate Switch _____________________________________ 35

4.3.2 Dimensioning oil cooling systems - cooling power __________________________________ 35

4.5.1 CE 13 - Horizontal assembly - Forced Lubrication With Suction Pump _________________ 37

4.5.2 CE 13 - Horizontal assembly - Forced Lubrication With Oil Return By Fall Down ________ 37

4.5.3 CE 13 - Vertical Down Assy - Forced Lubrication With Oil Return By Suction ___________ 38

4.5.4 CE 13 - Horizontal Assy - Forced Lubrication With Oil Return By Fall Down ____________ 38

4.5.5 CE 20 - Horizontal Assembly - Forced Lubrication With Suction Pump _________________ 39

4.5.6 CE 20 - Horizontal Assembly - Forced Lubrication With Oil Return By Fall Down ________ 39

4.5.7 CE 20 - Horizontal Assembly - Forced Lubrication With Oil Return By Fall Down ________ 40

4.5.8 CE 20 - Horizontal Assembly - Forced Lubrication With Suction Pump _________________ 40

4.5.9 CE 20 - Vertical Down Assembly - Forced Lubrication With Suction Pump ______________ 41

4.5.10 CE 20 Vertical Down Assy - Forced Lubrication With Oil Return By Fall Down _________ 41

4.6 Assembling Positions & Lubrication - CE 11 ____________________________________________ 42

4.7 Assembling Positions & Lubrication - CE 12 ____________________________________________ 44

4.8 Assembling Positions & Lubrication - CE 13 & CE13+ ____________________________________ 46

4.9 Assembling Positions & Lubrication - CE 14 & CE 15 ____________________________________ 48