USE AND MAINTENANCE MANUAL

2-Speed Gearboxes Series CE

M

.CE.GEN.ENG.DOCX

Issued

2018

Rev.03

Page 29 / 59

3.5

G

EARBOX

O

UTPUT

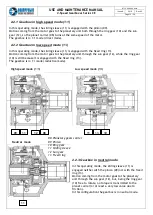

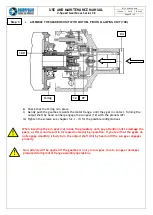

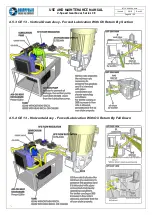

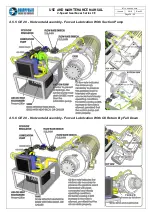

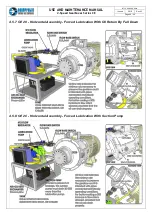

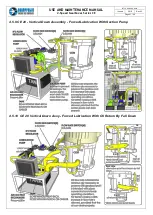

3.5.1 Verifying gearbox output loading capacity

Gearboxes can be supplied in shaft-output or flange-output configuration.

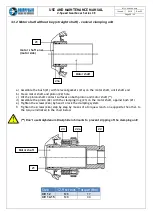

Shaft-output

is normally used when the gearbox is assembled coaxial to the machine or connected to

it by means of a timing belt or a gear (1).

In these cases, the radial forces are usually low-medium but they're applied far from the gearbox

bearings, creating a multiplying effect on the bearings load.

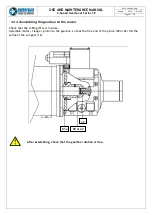

Flange-output

is normally used when the connection to the machine is made by means of Poly-V belts

(or similar) that transmit the torque by friction. In this case, the belt is usually wide and the belt

tension can be very high.

Using flange output gearboxes allows mounting the pulley according to drawing (2): the radial force is

applied in between the output bearings so that the load is proportionally held by both of them.

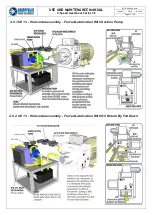

It is always necessary to verify the gearbox bearings life, referring to the data indicated on chapter

3.5.2.

In case the bearings life is too low, it is necessary to modify the machine design so that the radial force

is better distributed on the gearbox output bearings.

If this is not possible, the machine should be equipped with an additional support for the radial force.

(1) Shaft-output gearbox

The loads (F) are usually low-medium and

they're applied far from the gearbox bearings.

(2) Flange-output gearbox

The loads (F) are usually high and they're

applied in between the gearbox bearings.

F

F

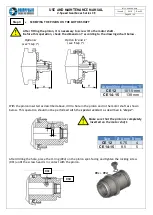

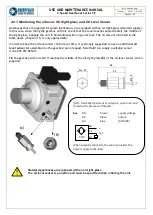

When using helical gears on the output side, an axial thrust arises, whatever output

configuration is used, together with the radial force.

It is always necessary to verify if the bearings can hold both the radial and the axial force

and to calculate their life accordingly.

In many cases, the axial force can reduce the bearings life significantly, so an additional

support should be foreseen to withstand it.