USE AND MAINTENANCE MANUAL

2-Speed Gearboxes Series CE

M

.CE.GEN.ENG.DOCX

Issued

2018

Rev.03

Page 32 / 59

4.2

S

PLASH

L

UBRICATION

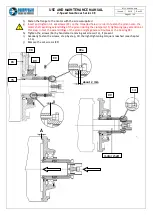

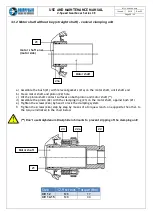

Splash lubrication is used when there are frequent shifting operations, frequent speed changes, variable

turning speeds and frequent machine downtimes such as, for example, rests for tool changes.

This lubrication system is suitable only for applications with maximum input speed 4500 rpm and in

the assembling positions indicated below.

In all other cases, recirculating lubrication must be used.

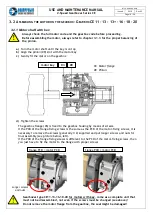

For CE 16-18-20 gearboxes and for vertical upwards assembling position, splash

lubrication is not allowed. For such gearboxes and for all vertical upwards assembling

positions, only recirculating oil lubrication is allowed.

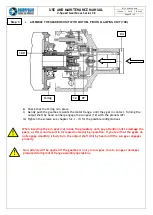

Before operating the gearbox, pour oil inside it until it reaches the oil level, according to the table

below, then plug the unit.

The oil for splash lubrication must have a viscosity according to ISO VG 68, it must be compatible

with sealing elements, it must have good resistance to aging and it should develop a high protection

towards corrosion and wear.

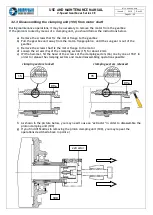

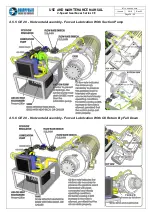

Suitable assembling positions

for Splash Lubrication

CE 11

CE 12

CE 13-13+

CE 14-15

CE 16-18-20

Horizontal standard

Maximum input speed 4500 rpm

B5

OPP

YES

YES

YES

YES

NO

Horizontal turned

Maximum input speed 4500 rpm

B5

OPP

YES

YES

YES

YES

NO

Vertical downwards

Maximum input speed 4500 rpm

V1

VFB

VPB

NO

YES

NO

YES

NO

Vertical upwards

V35

VFA

VPA

NO

NO

NO

NO

NO

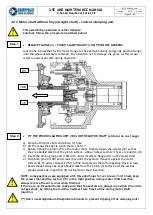

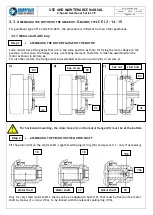

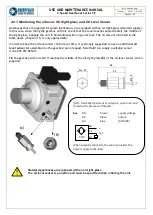

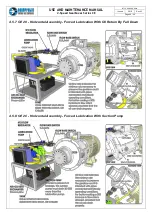

Assembling

position

Approx. oil amount in

liters

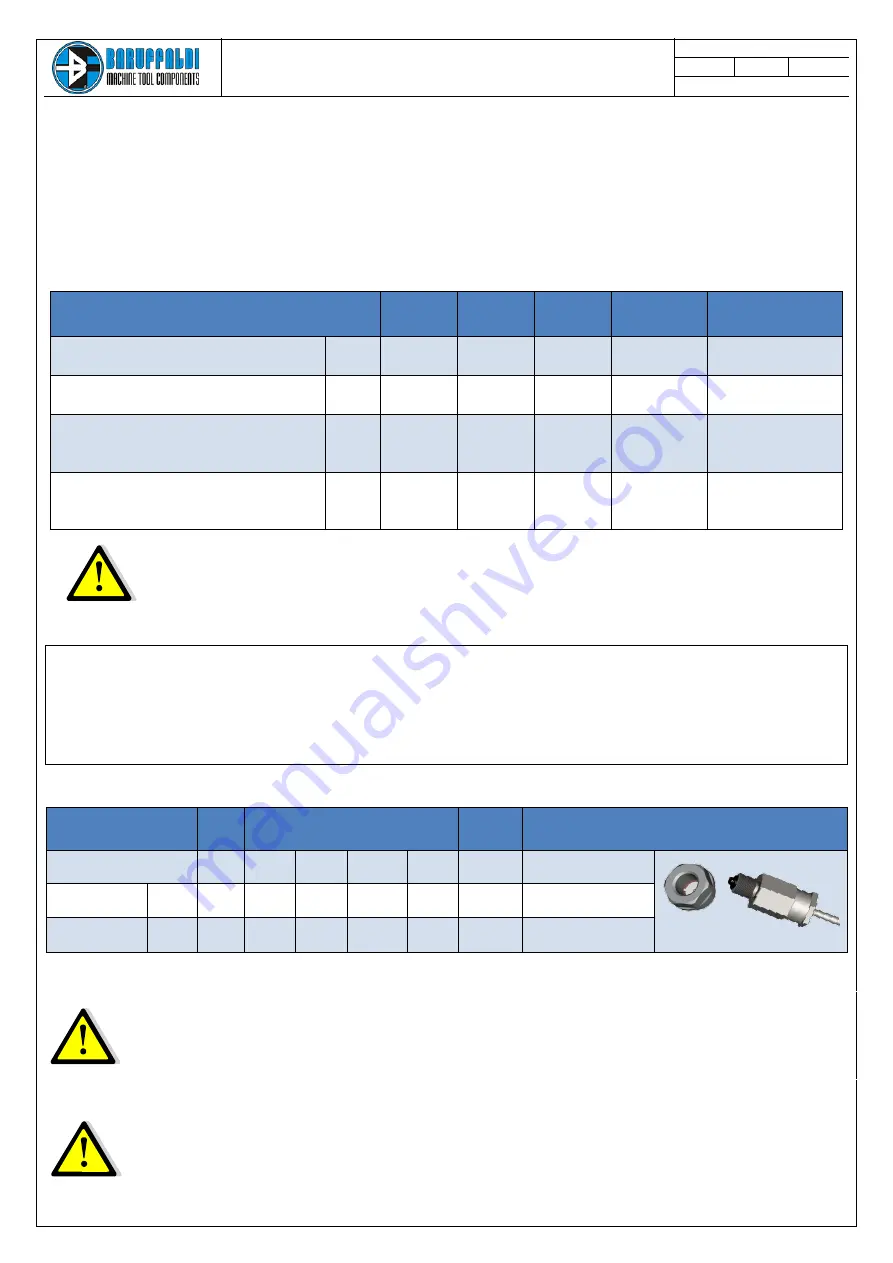

Oil level indicator

Gearbox size

CE11

CE12

CE13

CE13+

CE14

CE 15

CE 16-18-20

Horizontal

OPP

B5

0,6

1,1

2,2

2,8

3,1

3,3

X

Vertical

down

VFP

V1

X

0,5

X

X

1,5

1,6

X

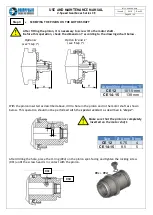

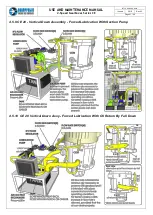

All gearboxes are supplied without oil.

Before operating a gearbox equipped for splash lubrication, fill it with oil until it reaches

the middle of the oil sight-glass or the oil level sensor, if supplied.

The oil amount indicated above is only indicative.

Oil level must be checked periodically, to avoid lack of lubrication over time.

In any case, oil must be replaced at least every 5000 hrs of work.