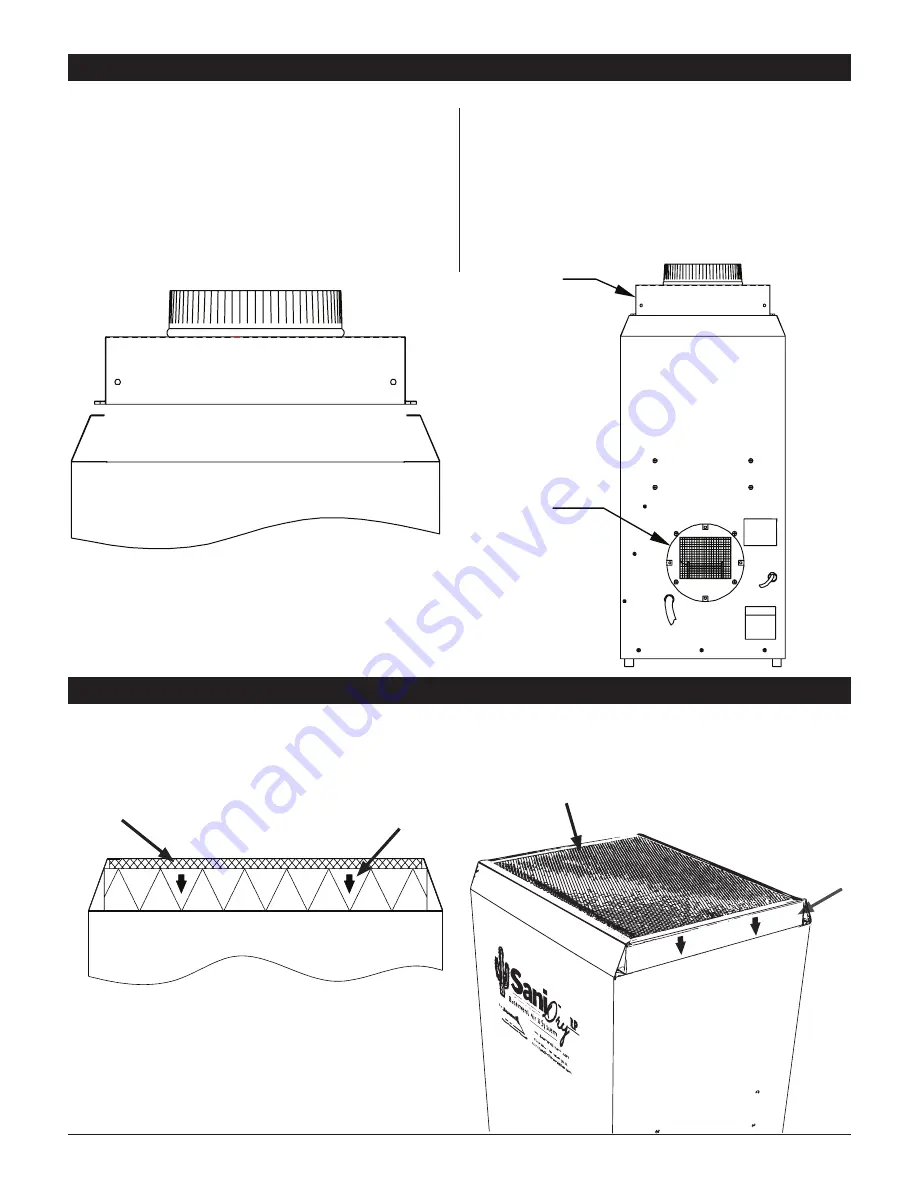

Ductable

Inlet

Exhaust

Collar

SaniDry XP DUCTABLE INLET MOUNTING

Ductable inlet instructions

1. Remove the Filters from the unit.

2. Remove the ductable inlet from the box and remove the

release paper from the tape on the inlet flanges.

3. Center the inlet above the filter guides and attach the inlet to

the guides.

4. Replace the filters in the unit.

exhaust Collar Mounting instructions

5. Remove the exhaust collar from the box and bend the tabs in.

6. Place the collar over the blower outlet and line up the tabs

with the holes in the cabinet.

7. Using (4) screws from the kit, attach the collar to the unit.

collar.

Ductable

Inlet

Exhaust

Collar

10

SaniDry XP Installer’s & Owner’s Manual

SaniDry XP FILTER INSTALLATION INSTRUCTIONS

Instructions: To prevent damaging the aluminum filter, place it “mesh-side up” on top of

the pleated filter and slide them both into the filter slot.

aluminum filter with

aluminum grid up.

Pleated filter with air flow

arrows pointed down.

Pleated filter with

air flow arrows

pointed down.

aluminum mesh filter

with aluminum grid up.

Summary of Contents for SD109 SaniDry XP

Page 1: ......