60-2

9424200996

Auxiliary Overvoltage (59X) Test

BE1-11

m

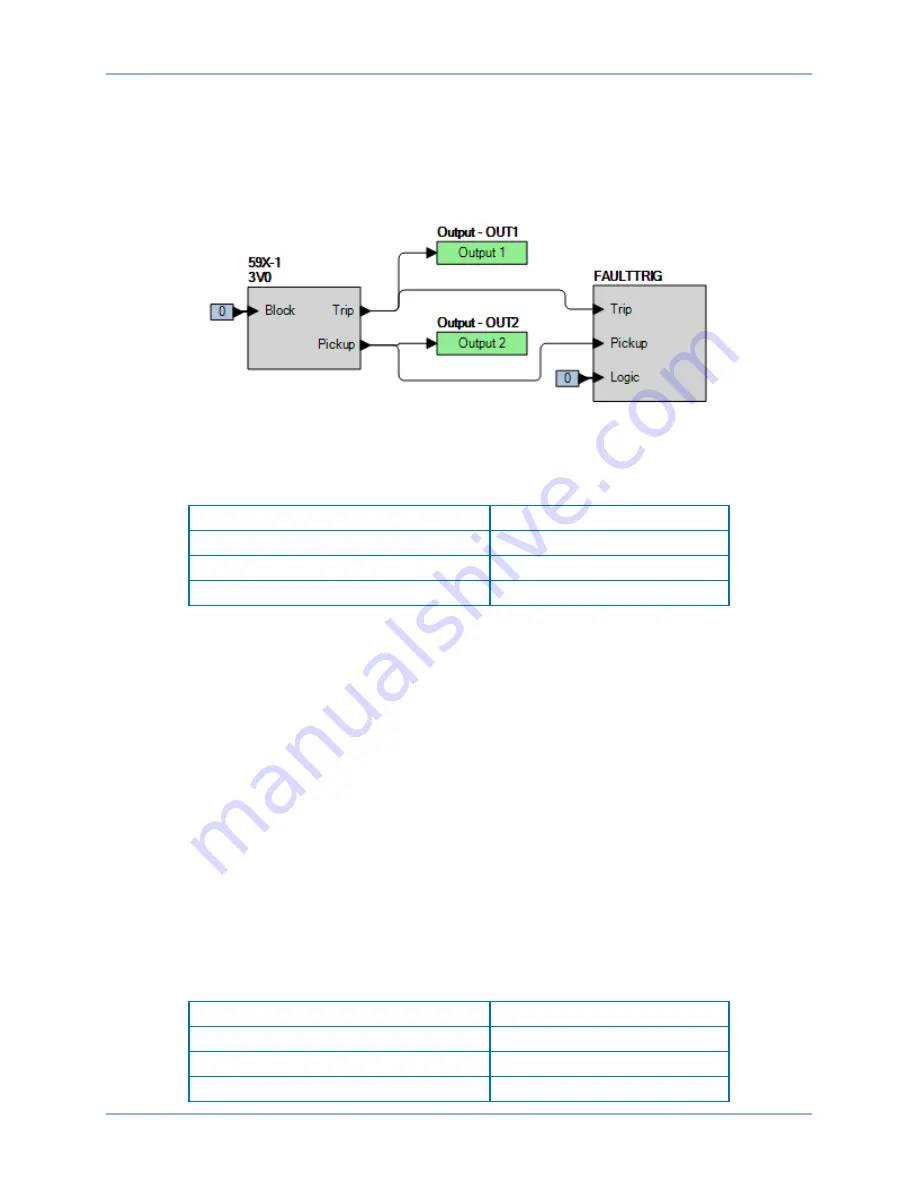

Step 2: Use BESTCOMS

Plus

to configure the BESTlogic

Plus

programmable logic shown in Figure

•

Blocking is disabled.

•

OUT1 closes for 59X-1 Trip.

•

OUT2 closes for 59X-1 Pickup.

•

Fault recording is enabled.

Figure 60-1. BESTlogic

Plus

Settings (3V0 Mode)

Step 3: Use BESTCOMS

Plus

to open the Protection, Voltage, Overvoltage (59X-1) screen and send

the first row of test settings in Table 60-2 to the BE1-11

m

.

Table 60-2. Pickup Test Settings (3V0 Mode)

Pickup Setting

Time Delay

115 V

50 ms

65 V

50 ms

20 V

50 ms

Step 4: Prepare to monitor the 59X-1 function operation. Operation can be verified by monitoring OUT2

(see Figure 60-1).

Step 5: Connect and apply a 150 Vac, three-phase voltage source to terminals C13 (A-phase), C14 (B-

phase), C15 (C-phase), and C16 (neutral).

Step 6: Slowly increase the A-phase voltage until OUT2 closes around 265 volts (150 Vac n

115 V 3V0 pickup setting) and record the pickup. Verify that there is a 59X-1-3V0 target on the

front-panel display. Slowly decrease the A-phase voltage until OUT2 opens and record the

dropout. Reset the target.

Step 7: Verify the pickup and dropout accuracy at a pickup setting of 65 V and 20 V as listed in Table

60-2. Record the results.

Step 8: (Optional.) Repeat steps 1 through 7 for the B-phase and C-phase voltage inputs.

Step 9: (Optional.) Repeat steps 1 through 8 for settings group 1, 2, and 3.

Step 10: (Optional.) Repeat steps 1 through 9 for 59X-2.

Timing Verification (3V0 Mode)

Step 1: Use BESTCOMS

Plus

to open the Protection, Voltage, Overvoltage (59X-1) screen and send

the first row of test settings in Table 60-3 to the BE1-11

m

for settings group 0.

Table 60-3. Timing Test Settings (3V0 Mode)

Pickup Setting

Time Delay

65 V

2,000 ms

65 V

5,000 ms

65 V

10,000 ms

Summary of Contents for BE1-11m

Page 8: ...vi 9424200996 Revision History BE1 11m...

Page 12: ...x 9424200996 Contents BE1 11m...

Page 21: ...9424200996 1 9 BE1 11m Introduction Figure 1 1 Style Chart...

Page 22: ...1 10 9424200996 Introduction BE1 11m...

Page 40: ...3 6 9424200996 Controls and Indicators BE1 11m Figure 3 3 Front Panel Display Setup Screen...

Page 54: ...5 6 9424200996 Phase Undervoltage 27P Protection BE1 11m...

Page 56: ...6 2 9424200996 Negative Sequence Voltage 47 Protection BE1 11m...

Page 61: ...9424200996 7 5 BE1 11m Phase Overvoltage 59P Protection Figure 7 3 Overvoltage Settings Screen...

Page 62: ...7 6 9424200996 Phase Overvoltage 59P Protection BE1 11m...

Page 68: ...8 6 9424200996 Auxiliary Overvoltage 59X Protection BE1 11m...

Page 80: ...12 4 9424200996 Instantaneous Overcurrent 50 Protection BE1 11m...

Page 84: ...13 4 9424200996 Breaker Failure 50BF Protection BE1 11m...

Page 92: ...14 8 9424200996 Inverse Overcurrent 51 Protection BE1 11m...

Page 105: ...9424200996 18 3 BE1 11m Power Factor 55 Protection Figure 18 2 Power Factor Settings Screen...

Page 106: ...18 4 9424200996 Power Factor 55 Protection BE1 11m...

Page 110: ...19 4 9424200996 Resistance Temperature Detector 49RTD Protection BE1 11m...

Page 118: ...20 8 9424200996 Thermal Curve 49TC Protection BE1 11m...

Page 122: ...22 2 9424200996 Starts per Time Interval 66 Protection BE1 11m...

Page 124: ...23 2 9424200996 Restart Inhibit Protection BE1 11m...

Page 140: ...28 4 9424200996 Breaker Control Switch 101 BE1 11m...

Page 148: ...29 8 9424200996 Setting Groups BE1 11m...

Page 156: ...30 8 9424200996 Metering BE1 11m Figure 30 11 RTD Meter Screen...

Page 158: ...31 2 9424200996 Digital Points BE1 11m Figure 31 2 Digital Points Monitor Screen...

Page 177: ...9424200996 34 5 BE1 11m Motor Reporting Figure 34 9 Learned Motor Data Screen...

Page 178: ...34 6 9424200996 Motor Reporting BE1 11m...

Page 184: ...35 6 9424200996 Alarms BE1 11m...

Page 186: ...36 2 9424200996 Differential Reporting BE1 11m...

Page 196: ...38 4 9424200996 Demands BE1 11m...

Page 198: ...39 2 9424200996 Load Profile BE1 11m...

Page 208: ...41 6 9424200996 Trip Circuit Monitor 52TCM BE1 11m...

Page 212: ...42 4 9424200996 Fuse Loss 60FL BE1 11m...

Page 218: ...43 6 9424200996 BESTnet Plus BE1 11m Figure 43 8 Power Quality Page...

Page 221: ...9424200996 44 3 BE1 11m Mounting Figure 44 3 Case Side Dimensions...

Page 235: ...9424200996 45 5 BE1 11m Terminals and Connectors Figure 45 7 Example of Reversed CT Polarity...

Page 236: ...45 6 9424200996 Terminals and Connectors BE1 11m...

Page 269: ...9424200996 48 15 BE1 11m BESTlogic Plus Figure 48 4 Logic Page 1 for Default Logic...

Page 288: ...49 10 9424200996 Communication BE1 11m Figure 49 14 Modbus Mapping Screen...

Page 306: ...52 4 9424200996 Device Information BE1 11m...

Page 314: ...53 8 9424200996 Configuration BE1 11m Figure 53 3 Display Units Screen...

Page 318: ...54 4 9424200996 Introduction to Testing BE1 11m...

Page 330: ...56 6 9424200996 Commissioning Testing BE1 11m...

Page 336: ...58 4 9424200996 Phase Undervoltage 27P Test BE1 11m...

Page 340: ...59 4 9424200996 Phase Overvoltage 59P Test BE1 11m...

Page 352: ...60 12 9424200996 Auxiliary Overvoltage 59X Test BE1 11m...

Page 360: ...61 8 9424200996 Frequency 81 Test BE1 11m...

Page 364: ...62 4 9424200996 Instantaneous Undercurrent 37 Test BE1 11m...

Page 376: ...63 12 9424200996 Instantaneous Overcurrent 50 Test BE1 11m...

Page 396: ...65 16 9424200996 Inverse Overcurrent 51 Test BE1 11m...

Page 408: ...67 6 9424200996 Power 32 Test BE1 11m...

Page 412: ...68 4 9424200996 Loss of Excitation Reverse Var Based 40Q Test BE1 11m...

Page 426: ...70 10 9424200996 Thermal Curve 49TC Test BE1 11m...

Page 432: ...72 4 9424200996 Starts per Time Interval 66 Test BE1 11m...

Page 436: ...73 4 9424200996 Restart Inhibit Test BE1 11m...

Page 440: ...74 4 9424200996 Virtual Control Switches 43 Test BE1 11m...

Page 450: ...75 10 9424200996 Logic Timers 62 Test BE1 11m...

Page 464: ...79 8 9424200996 Troubleshooting BE1 11m...

Page 480: ...80 16 9424200996 Specifications BE1 11m...

Page 600: ...84 56 9424200996 Settings Calculation Examples BE1 11m Figure 84 70 Logic Page 4 Part 1...

Page 602: ...84 58 9424200996 Settings Calculation Examples BE1 11m...

Page 608: ...85 6 9424200996 BESTCOMSPlus Settings Loader Tool BE1 11m...

Page 609: ......