BE1-40Q Installation

4-1

SECTION 4 • INSTALLATION

GENERAL

When not shipped as part of a control or switchgear panel, relays are shipped in sturdy cartons to prevent

damage during transit. Immediately upon receipt of a relay, check the model and style number against the

requisition and packing list to see that they agree. Visually inspect the relay for damage that may have

occurred during shipment. If there is evidence of damage, immediately file a claim with the carrier and notify

the Regional Sales Office, or contact the Sales Representative at Basler Electric, Highland, Illinois.

In the event the BE1-40Q Relay is not to be installed immediately, store it in the original shipping carton in

a moisture and dust free environment. See Section 5 for further information. When the relay is to be placed

in service, it is recommended that the Operational Test Procedure (Section 5) be performed prior to

installation.

RELAY OPERATING PRECAUTIONS

Before installation or operation of the relay, note the following precautions:

1.

A minimum of 0.2 A in the output circuit is required to ensure operation of current operated

targets.

2.

The relay is a solid-state device. If a wiring insulation test is required, remove the connection

plugs and withdraw the cradle from its case.

3.

When the connection plugs are removed, the relay is disconnected from the operating circuit and

will not provide system protection. Always be sure that external operating (monitored) conditions

are stable before removing a relay for inspection, test, or service.

4.

Be sure the relay case is hard wired to earth ground using the ground terminal on the rear of the

unit. It is recommended to use a separate ground lead to the ground bus for each relay.

DIELECTRIC TEST

In accordance with IEC 255-5 and ANSI/IEEE C37.90-1989, one-minute dielectric tests (high potential) may

be performed as follows:

All circuits to ground:

2121 Vdc.

Input to output circuts:

1500 Vac or 2121 Vdc.

MOUNTING

Because the relay is of solid-state design, it does not have to be mounted vertically. Any convenient

mounting angle may be chosen. Relay outline dimensions and panel drilling diagrams are supplied in

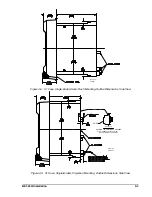

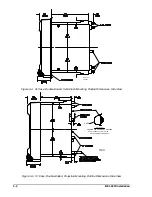

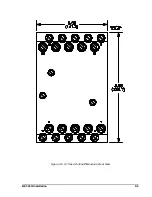

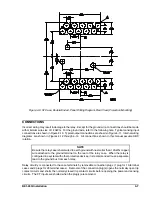

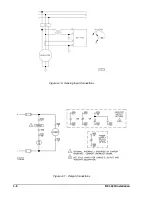

Figures 4-1 through 4-9.

Summary of Contents for BE1-40Q

Page 13: ...2 2 BE1 40Q Human Machine Interface Figure 2 1 Location of Controls and Indicators ...

Page 19: ...4 2 BE1 40Q Installation 2 02 01 D1427 01 Figure 4 1 S1 Case Outline Dimensions Front View ...

Page 22: ...BE1 40Q Installation 4 5 Figure 4 6 S1 Case Outline Dimensions Rear View ...

Page 25: ...4 8 BE1 40Q Installation Figure 4 10 Sensing Input Connections Figure 4 11 Output Connections ...

Page 35: ...5 8 BE1 40Q Setting and Testing Figure 5 4 Blank Graph ...