BE1-46N Manual Change Information

7-1

SECTION 7 • MANUAL CHANGE INFORMATION

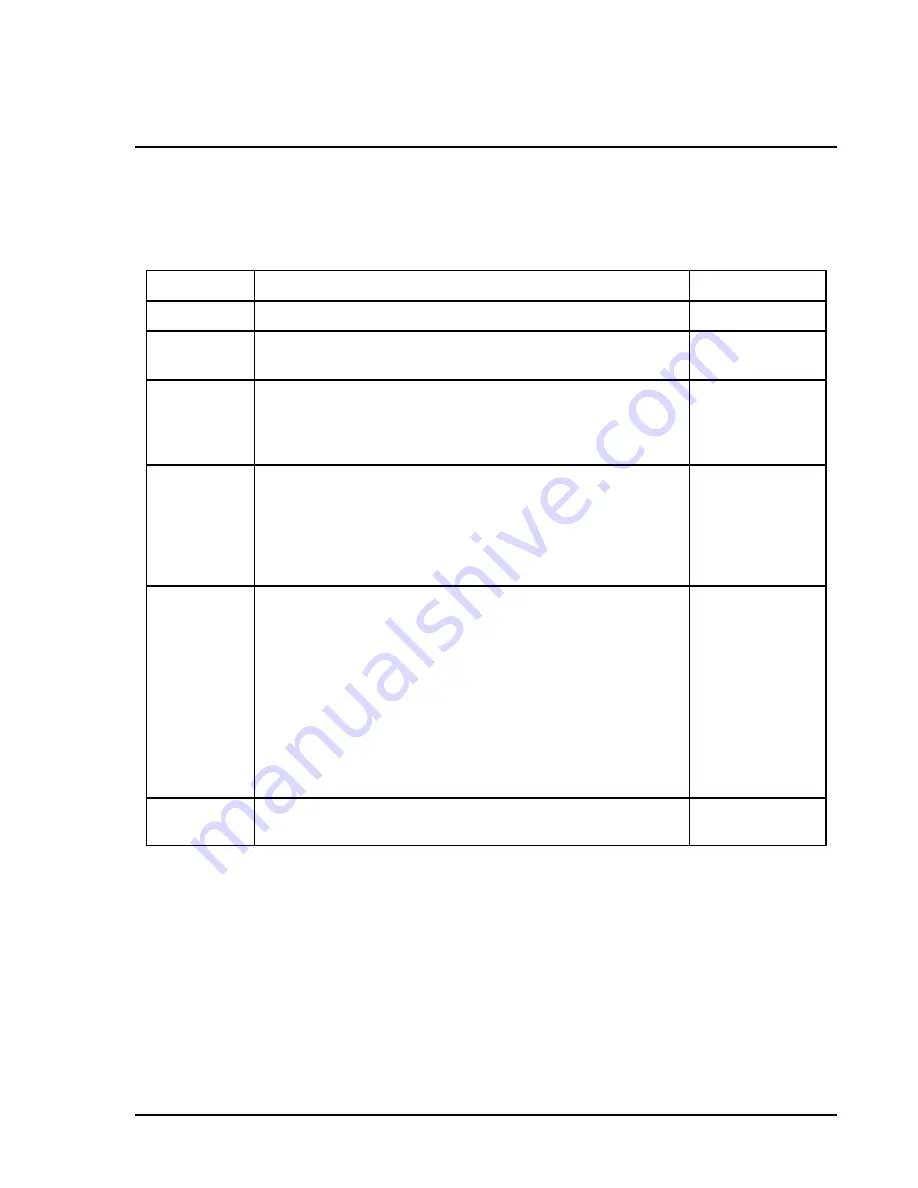

SUMMARY AND CROSS REFERENCE GUIDE

This section contains information concerning the previous editions of the manual. The substantive changes

to date are summarized in the Table 7-1.

Table 7-1. Summary of Changes

Revision

Summary of Changes

ECA(ECO)/Date

A

Changed case terminal polarity for the remote indicator.

7792 / 04-25-86

B

Changed Instructional Manual format and presentation to

increase readability and correct minor errors.

12206 / 09-30-91

C

Changed

Section 1, Specifications, and Section 4, Installation

to reflect ECA changes in the relay. Corrected typographical

errors in

Section 3. Divided Section 4, Installation into two

sections

Section 4, Installation and Section 5, Testing.

14961 / 02-28-95

D

Changed all sections to include one ampere sensing input

range as standard styles. Changed

Section 1, Specifications,

and

Section 3 to reflect the changes in the relay. Changed

Figures 4-9 and 4-11 to remove power supply status references.

Updated Figures 1-1 and 3-2 to reflect changes made in the

relay.

15187 / 08-02-95

E

Deleted all references to Service Manual. Corrected Figure 1-1

“Style Number Identification Chart” Power Supply Type T from

“230 Vac” to “240 Vac” and Type S, removed “Switchable.”

Deleted IEC 255-5 from Isolation Specification and Section 4

under Dielectric Test. Added UL Recognition to Specifications.

Added 1 amp CT values to Section 3 for setting considerations.

Changed

Section 3 to include power supply status output.

Changed Figures 3-1, 4-9, and 4-11 to reflect this change.

Added “Max Time” to Section 3. Timing in Section 5, changed

Step 5 from “MAX TIME” to “time required for.” Changed the

format of the manual and corrected minor errors.

1591 / 11-24-95

F

Updated the drawings in section 4 to reflect the latest S1 Case

drawings.

12263/02-09-01

www

. ElectricalPartManuals

. com