BE1-50/51M-222 Testing

5-5

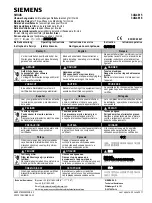

CAUTION

Trip circuit voltage is present at the front panel test points. When shorting the test

points, use insulated jumpers to avoid contact with these voltages.

Manual Trip Test

Perform preliminary setup:

Connect test setup as shown in Figure 5-2.

Insure that SW8 switches are set correctly: SW8-1 for operating frequency, SW8-2 to OFF (no

instantaneous delay), SW8-3 to OFF (no instantaneous delay), and SW8-4 to OFF (selects

instantaneous reset).

Set TIME DIAL to 4.5.

Set CURVE to S

Set TIME PICKUP to 1.0.

Set INST PICKUP to 01.

Step 1. Set target current source to 1.0 ampere, ac.

Step 2. Apply 0.9 ampere input current to terminals 8 and 9.

Step 3. Connect a jumper between TIME MANUAL TRIP test points. Check that TIME target operates.

Step 4. Connect a jumper between INST MANUAL TRIP test points. Check that INST target operates.

Step 5. Reset targets.

Integrating Reset Test

Perform preliminary setup:

Insure that SW8 switches are set correctly: SW8-1 for operating frequency, SW8-2 to OFF (no

instantaneous delay), SW8-3 to OFF (no instantaneous delay), and SW8-4 to ON (selects integrating

reset).

Set TIME DIAL to 4.5.

Set CURVE to I.

Set TIME PICKUP to 1.0.

Set INST PICKUP to 90.

Step 1. Set target current source to 1.0 ampere, ac.

Step 2. Read all of Step 3 before beginning Step 3.

Step 3. Apply 4.0 amperes input current to terminals 8 and 9. After the unit trips, remove the input current

for 20 ±0.25 seconds, then reapply the 4.0 amperes input current. Record the elapsed time from

the reapplication of input current to the output retrip.

Result: Elapsed time should be 1.55 ±0.3 seconds.

Summary of Contents for BE1-50/51M-222

Page 29: ...BE1 50 51M 222 Installation 4 2 Figure 4 1 Outline Dimensions C1 Case ...

Page 30: ...BE1 50 51M 222 Installation 4 3 Figure 4 2 Panel Drilling Diagram C1 Case ...

Page 32: ...BE1 50 51M 222 Installation 4 5 Figure 4 4 DC Control Connections ...

Page 33: ...BE1 50 51M 222 Installation 4 6 Figure 4 5 BE1 50 51M 222 Overcurrent Relay Rear View ...