5-

7

BE1-79S Operational Test

NOTE

The voltage monitor is now set to allow reclosure when the line and bus voltage

conditions established in STEP 8 are encountered in the protective system.

NOTE

The voltage monitor is now set to inhibit reclosure when the line and/or bus conditions

established in STEP 9 are encountered in the protective system.

NOTE

Steps 16 through 20 provide a means of calibrating the Maximum Trial timer . This timer

is only present when Reset Timer Option B or C is installed. For all other relays the

operational test is concluded .

NOTE

The voltage monitor is now verified to operate in accordance with the previous

selections.

the DB/OV indicator just lights.

Step 9. If OV was selected (STEP 4) adjust the T1 (bus) and/or T2 (line) output voltages to the desired

higher voltage limit such that, for anticipated voltages above the setting(s), reclosure will not

occur.

Step 10. Slowly adjust the OV voltage level adjustments that correspond with the selected conditions until

the associated indicator just lights.

To check the operation of the relay with the resulting set-up, perform the following steps:

Step 11. Momentarily press switch S1 to energize relay K1.

Step 12. Close switch S4 to supply RI signal to relay.

Step 13. Adjust the T1 (bus) and T2 (line) outputs to within reclosure enable zones established in the

previous steps.

Step 14. Press and release switch S2. Relay K1 should momentarily trip, then reset.

Step 15. If the OV mode was selected, adjust the appropriate input voltage (T1 or T2) until the voltage

exceeds the OV level. With relay K1 energized, press and release switch S2. Relay K1 should trip,

but no reclosure should occur.

Step 16. Set Condition Switches 1 and 2 down, 3 through 5 up .

Step 17. Set Mode Switches 1 down, 2 up .

Step 18. Place a voltmeter between pin 39 of Voltage Monitor board and ground. (Should read 0 volts. )

Step 19. Apply a high (tripping) signal to relay terminal 14 (52b) and note the time it takes until terminal 39

goes high . Time should be as follows.

For Reset Option B: 95 +10 seconds

For Reset Option C: 15 +2 seconds

Step 20. If time period falls outside of the specified tolerance, adjust potentiometer R60 as required .

Summary of Contents for BE1-79S

Page 26: ...BE1 79S Installation 4 5 Figure 4 5 S1 Case Panel Drilling Diagram Semi Flush Mounting...

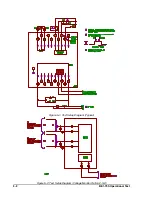

Page 28: ...BE1 79S Installation 4 7 Figure 4 8 Voltage Sensing Circuit Connections...

Page 29: ...4 8 BE1 79S Installation Figure 4 9 RI RC and 52b Sensing Circuit Connections...

Page 30: ...BE1 79S Installation 4 9 Figure 4 10 Internal Connection Diagram With Power Supply Status...