BE1-951

Protection and Control

4-35

If the target is enabled for the element, the target reporting function will record a target when the protective

function trip output is TRUE and the fault recording function trip logic expression is TRUE. See Section 6,

Reporting and Alarm Functions, Fault Reporting Functions for more information about target reporting.

BESTlogic Settings for the Directional Overpower Element

Logic settings for the 32 function are made using the SL-32 (settings logic-power) command. The settings

of this command determine whether the element is enabled or disabled. The SL command also provides

blocking control as determined by the logic expression assigned to the BLK input. See Table 4-27 for

directional overpower logic settings.

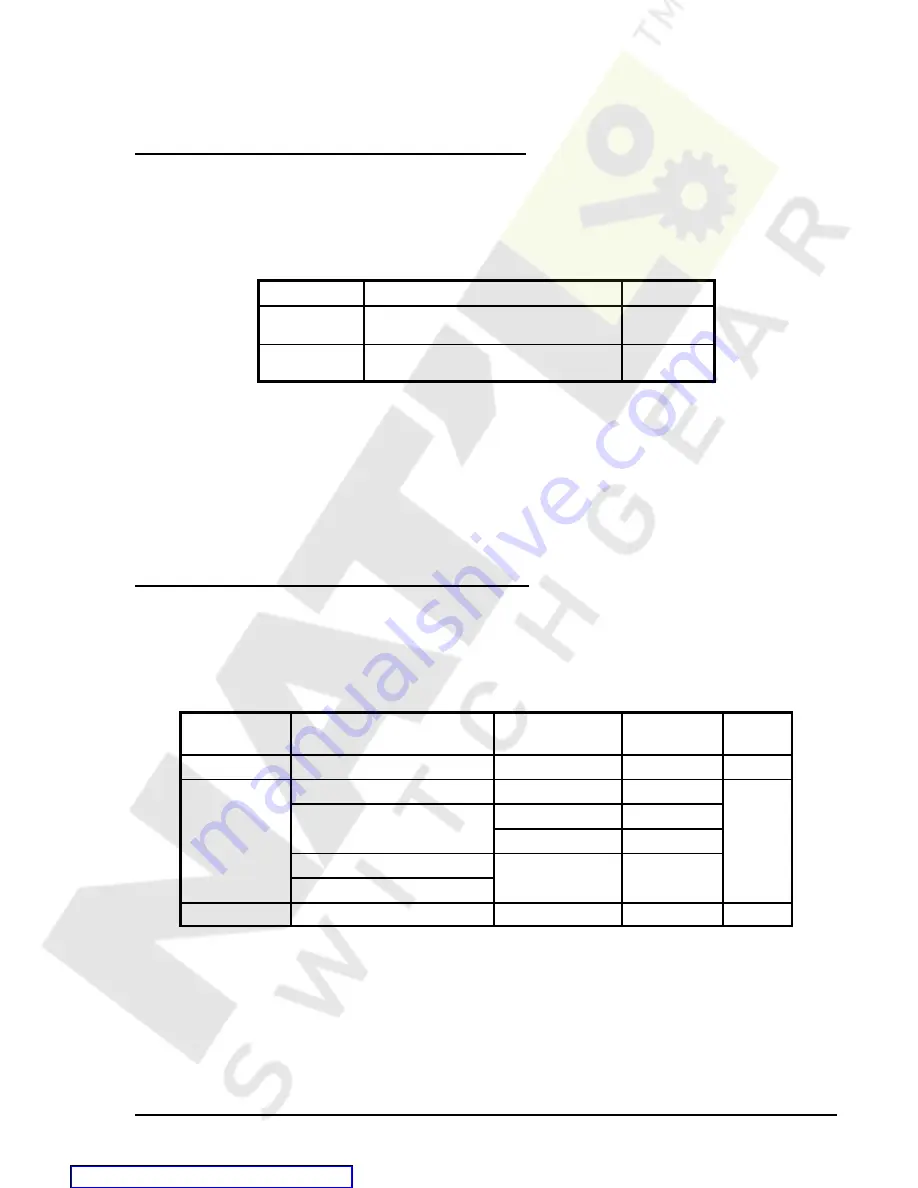

Table 4-27. Directional Overpower Logic settings

Function

Range/Purpose

Default

mode

0=Disable

1=enable

1

BLK logic

Logic expression that disables

function when true

0

SL-32 Command

Purpose:

Read or set logic for the Directional Overpower element

Syntax:

SL-32[=<mode>,<BLK logic>]

Comments:

Refer to Table 4-27 for settings definitions

SL-32 Command Example

Enable the 32 when IN3 is energized (= Block 32 when IN3 open):

>SL-32=1,/IN3

Operating Settings for the Directional Overpower Elements

Operating settings for the 32 elements consist of the pickup in secondary three-phase watts, time delay, and

forward/reverse mode setting. Settings are made using the S<g>-32 command. These settings can also be

viewed or changed at the front panel HMI using screen 5.x.4.1 where x equals 1 for setting group 0, and 2

for setting group 1. See Table 4-28 for the Directional Over Power Function Settings.

Table 4-28. Directional Over Power Function Settings

Setting

Range

Increment

Unit of

measure

Default

pu (pickup)

0=disabled, 1-6000

0.1 / 1

sec. watts

0

td

(time delay)

0 to 999 milliseconds

1

milliseconds

0

0.0 to 600 seconds

0.1 for 0.1 to 9.9

seconds

1.0 for 10 to 600

seconds

0 to 36,000 cycles (60 Hz)

7

cycles

0 to 30,000 cycles (50 Hz)

mode

F=Forward, R=Reverse

N/A

N/A

R

7

Time delays less than 10 cycles can be entered to the nearest 0.1 cycle from the HMI. All time

delays can be entered to the nearest 0.01 cycle from the ASCII command interface. Time delays

entered in cycles are converted to milliseconds or seconds. Increment precision after conversion

is limited to that appropriate for each of those units of measure.