Command Purpose

SG-CT2=1,WYE,NA,0

Ctr = 1, ct = wye, xfmr = na, no ground source.

SG-CT3=1,WYE,NA,0

Ctr = 1, ct = wye, xfmr = na, no ground source.

SG-CT4=1,WYE,NA,0

Ctr = 1, ct = wye, xfmr = na, no ground source.

SG-TRIGGER=87RT,87RPU,0

Enable 87RT to log and trigger fault recording.

S#-TAP87=MANUAL,2.00,3.80

set Tap 1 = 2.00 and Tap 2 = 3.80.

E Exit.

Y Save

settings.

Step 3:

Apply 2.0 amps of 60 Hz current to the A-phase Input 1. The OUT1 (87RT restrained trip)

output contact should close upon application of current.

Step 4:

Apply 300 Hz current on the source paralleled to A-phase Input 1 and slowly increase the

current from zero until OUT2 closes (and conversely, OUT1 opens).

Step 5:

Record the current magnitude from Step 4 that caused OUT 2 to close and OUT1 to open.

These output contact changes indicated that the 5

th

harmonic restraint function is now

restraining the 87RT operation.

Step 6:

Remove both 60 Hz and 300 Hz currents.

Step 7:

To arrive at a 5

th

harmonic inhibit percentage value, divide the magnitude of the applied 5

th

harmonic current (300 Hz) by the magnitude of the applied 60 Hz input current. For this

particular test, this value should be equal to 0.70 amperes @ 300 Hz

2 A @ 60 Hz = 35 %.

Verify that the 5

th

harmonic inhibit function restrains operation at the expected value based on

settings from Step 2.

Step 8:

(Optional.) Repeat Steps 2 through 7 for phases B and C.

Step 9:

(Optional.) Repeat Steps 2 through 8 for Setting Groups 1 through 3 using the CS/CO-

GROUP command to change setting groups.

Step 10: (Optional.) Repeat for each pair of CT inputs (CT1-CT3, CT1-CT4, CT2-CT3, CT2-CT4, and

CT3-CT4).

Unrestrained Pickup Verification

Purpose:

To verify the accuracy of the unrestrained operation of the 87 element.

Reference Commands:

SL-87, SL- VO, SG-CT, S(n)-87, S(n)-TAP87

Step 1:

Connect one current source to terminals B1, B2 (A-phase, Input 1). Refer to Figure 13-1. An

ohmmeter or continuity tester may be used to monitor output contact status.

Step 2:

Send the commands listed in Table 13-36 to the relay to setup a test of the pickup of the 87

elements.

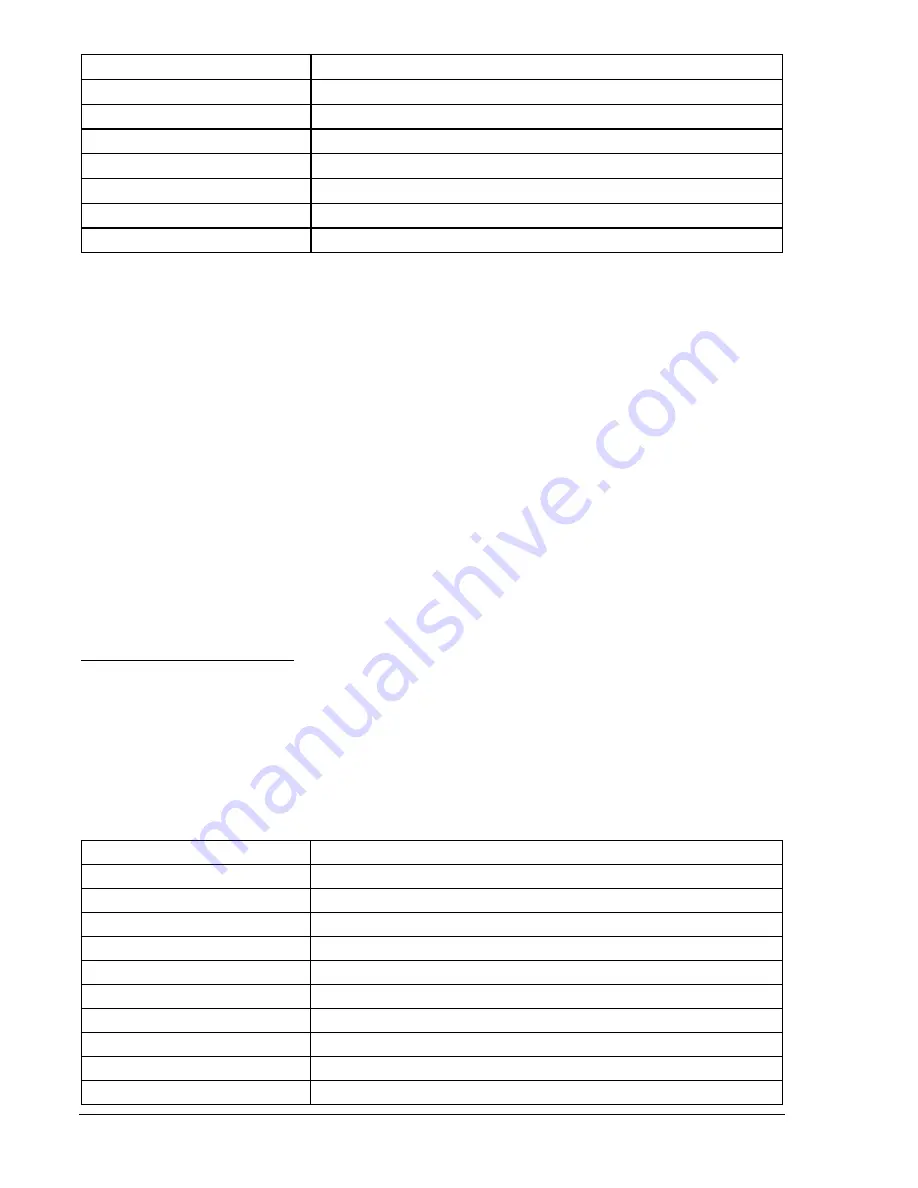

Table 13-36. 87 Elements Pickup Setup Commands

Command Purpose

A= Gain

access.

SL-N=NONE

Zero out custom logic settings/overwrite with logic = None settings.

Y Confirm

overwrite.

SL-N=UDIFF

Name custom logic for this test.

SL-87=1,0 Enables

87.

SL-VO1=87UT

Enables OUT1 to close with 87 unrestrained trip.

SL-VO2=5THHAR

Enables OUT2 to close when 5

th

harmonic restrains 87RT.

SG-CT1=1,WYE,NA,0

Ctr = 1, ct = wye, xfmr = na, no ground source.

SG-CT2=1,WYE,NA,0

Ctr = 1, ct = wye, xfmr = na, no ground source.

SG-CT3=1,WYE,NA,0

Ctr = 1, ct = wye, xfmr = na, no ground source.

13-50

BE1-CDS240 Testing and Maintenance

9365200990 Rev F

Summary of Contents for BE1-CDS240

Page 2: ......

Page 8: ...vi BE1 CDS240 Introduction 9365200990 Rev F This page intentionally left blank ...

Page 38: ...1 28 BE1 CDS240 General Information 9365200990 Rev F This page intentionally left blank ...

Page 40: ...ii BE1 CDS240 Quick Start 9365200990 Rev F This page intentionally left blank ...

Page 152: ...ii BE1 CDS240 Metering 9365200990 Rev F This page intentionally left blank ...

Page 226: ...iv BE1 CDS240 Application 9365200990 Rev F This page intentionally left blank ...

Page 286: ...ii BE1 CDS240 Security 9365200990 Rev F This page intentionally left blank ...

Page 290: ...9 4 BE1 CDS240 Security 9365200990 Rev F This page intentionally left blank ...

Page 292: ...ii BE1 CDS240 Human Machine Interface 9365200990 Rev F This page intentionally left blank ...

Page 306: ...10 14 BE1 CDS240 Human Machine Interface 9365200990 Rev F This page intentionally left blank ...

Page 308: ...ii BE1 CDS240 ASCII Command Interface 9365200990 Rev F This page intentionally left blank ...

Page 342: ...11 34 BE1 CDS240 ASCII Command Interface 9365200990 Rev F This page intentionally left blank ...

Page 349: ...Figure 12 5 Horizontal Rack Mount Front View 9365200990 Rev F BE1 CDS240 Installation 12 5 ...

Page 361: ...Figure 12 17 Typical DC Connection Diagrams 9365200990 Rev F BE1 CDS240 Installation 12 17 ...

Page 372: ...12 28 BE1 CDS240 Installation 9365200990 Rev F This page intentionally left blank ...

Page 468: ...13 92 BE1 CDS240 Testing and Maintenance 9365200990 Rev F This page intentionally left blank ...

Page 512: ...14 42 BE1 CDS240 BESTCOMS Software 9365200990 Rev F This page intentionally left blank ...

Page 544: ...ii BE1 CDS240 Terminal Communication 9365200990 Rev F This page intentionally left blank ...

Page 550: ...ii BE1 CDS240 Settings Calculations 9365200990 Rev F This page intentionally left blank ...

Page 578: ...D 28 BE1 CDS240 Settings Calculations 9365200990 Rev F This page intentionally left blank ...

Page 579: ......