Step 1. Calculate the Operating Slope S

i

.

The operating slope

S

i

is the ratio of the differential current (

I

op

) caused by the sum of all the mismatch

hanger (this can be compensated for in the tap calculation). You may choose to include

the no load taps may be adjusted without the relay taps

should be 10% * (n-1) where

The following errors are not included in the

operating slope value. (These sources of mismatch do not

It will offset the slope characteristic from the origin in the operate direction on the operate versus

and the

maximum slope

In the example, the tap factors were calculated

tap changer

position is included as

S

I

= (5% NLTC) + (10% LTC) + (10% CT) + (4% Relay) = 29%

sources versus the through current. The following sources of

I

op

current must be taken into account:

No load tap c

this source of mismatch if it is possible that

being reset.

Load tap changer.

Tap mismatch (assumed to negligible due to the fine tap adjustment available in the relay).

Quality of the CTs (If the saturation factor calculated previously is greater than 0.5, additional margin

is recommended. For SF<0.5, we assume that the CTs perform within the 10% limit defined in the

ANSI Accuracy Class. When accounting for CT error, the total CT error

n is the number of restraint current inputs (2 for two restraint relay, 3 for three restraint relay). If more

than one CT is nearing the performance limit, the errors tend to cancel.

Relay measuring errors. 4% applies to the BE1-CDS240 (2% per input circuit).

S

i

vary with through current so they affect the minpu setting only.)

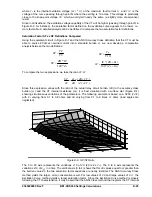

Transformer excitation current

IE

(assumed to be less than 4% of the self-cooled rating). This

mismatch does not vary with through current (load) so it tends to not add to the slope mismatch line.

restraint characteristic (see Figure D-10).

Unmonitored loads “

Iunmon

” such as station service or small capacitor banks in the differential zone

add to the constant excitation current.

When the saturation factor exceeds 0.5 on any of the CTs, CT saturation is likely. For this condition, the

BE1-CDS240 improves security by delaying restrained tripping by two cycles when the transient monitor

function detects operate (differential) current that is a result of CT saturation. For applications where the

saturation factor is greater than 0.5, additional slope margin is recommended. For applications where the

saturation factor exceeds 1.0, severe distortion is likely at high fault current

setting (60%)

is recommended. For more information, see Setting Note 4.

on system nominal ratings so the no load

a source of mismatch.

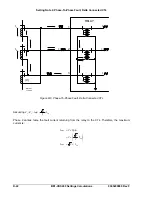

OFFSET

i

o

OFFSET

i

o

o

I

S

S

1

pu

min

M

I

S

pu

min

S

pu

min

M

AC

AB

M

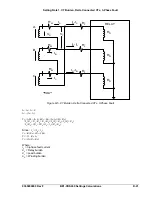

Choose slope setting S. The tripping slope S must be greater than S

Step 2.

current. Refer to Figure D-2, Slope and Operating Margin. A

slope margin of 10%

is

recom

i

to provide a safety margin

at the differential tripping characteristic knee point (intersection of the minimum pickup tripping

characteristic and the slope-tripping characteristic). This safety margin is required to

accommodate the additional mismatch caused by the excitation current and the unmonitored load

mended.

D-18

BE1-CDS240 Settings Calculations

9365200990 Rev F

Summary of Contents for BE1-CDS240

Page 2: ......

Page 8: ...vi BE1 CDS240 Introduction 9365200990 Rev F This page intentionally left blank ...

Page 38: ...1 28 BE1 CDS240 General Information 9365200990 Rev F This page intentionally left blank ...

Page 40: ...ii BE1 CDS240 Quick Start 9365200990 Rev F This page intentionally left blank ...

Page 152: ...ii BE1 CDS240 Metering 9365200990 Rev F This page intentionally left blank ...

Page 226: ...iv BE1 CDS240 Application 9365200990 Rev F This page intentionally left blank ...

Page 286: ...ii BE1 CDS240 Security 9365200990 Rev F This page intentionally left blank ...

Page 290: ...9 4 BE1 CDS240 Security 9365200990 Rev F This page intentionally left blank ...

Page 292: ...ii BE1 CDS240 Human Machine Interface 9365200990 Rev F This page intentionally left blank ...

Page 306: ...10 14 BE1 CDS240 Human Machine Interface 9365200990 Rev F This page intentionally left blank ...

Page 308: ...ii BE1 CDS240 ASCII Command Interface 9365200990 Rev F This page intentionally left blank ...

Page 342: ...11 34 BE1 CDS240 ASCII Command Interface 9365200990 Rev F This page intentionally left blank ...

Page 349: ...Figure 12 5 Horizontal Rack Mount Front View 9365200990 Rev F BE1 CDS240 Installation 12 5 ...

Page 361: ...Figure 12 17 Typical DC Connection Diagrams 9365200990 Rev F BE1 CDS240 Installation 12 17 ...

Page 372: ...12 28 BE1 CDS240 Installation 9365200990 Rev F This page intentionally left blank ...

Page 468: ...13 92 BE1 CDS240 Testing and Maintenance 9365200990 Rev F This page intentionally left blank ...

Page 512: ...14 42 BE1 CDS240 BESTCOMS Software 9365200990 Rev F This page intentionally left blank ...

Page 544: ...ii BE1 CDS240 Terminal Communication 9365200990 Rev F This page intentionally left blank ...

Page 550: ...ii BE1 CDS240 Settings Calculations 9365200990 Rev F This page intentionally left blank ...

Page 578: ...D 28 BE1 CDS240 Settings Calculations 9365200990 Rev F This page intentionally left blank ...

Page 579: ......