9365200990 Rev F

BE1-CDS240 Testing and Maintenance

13-57

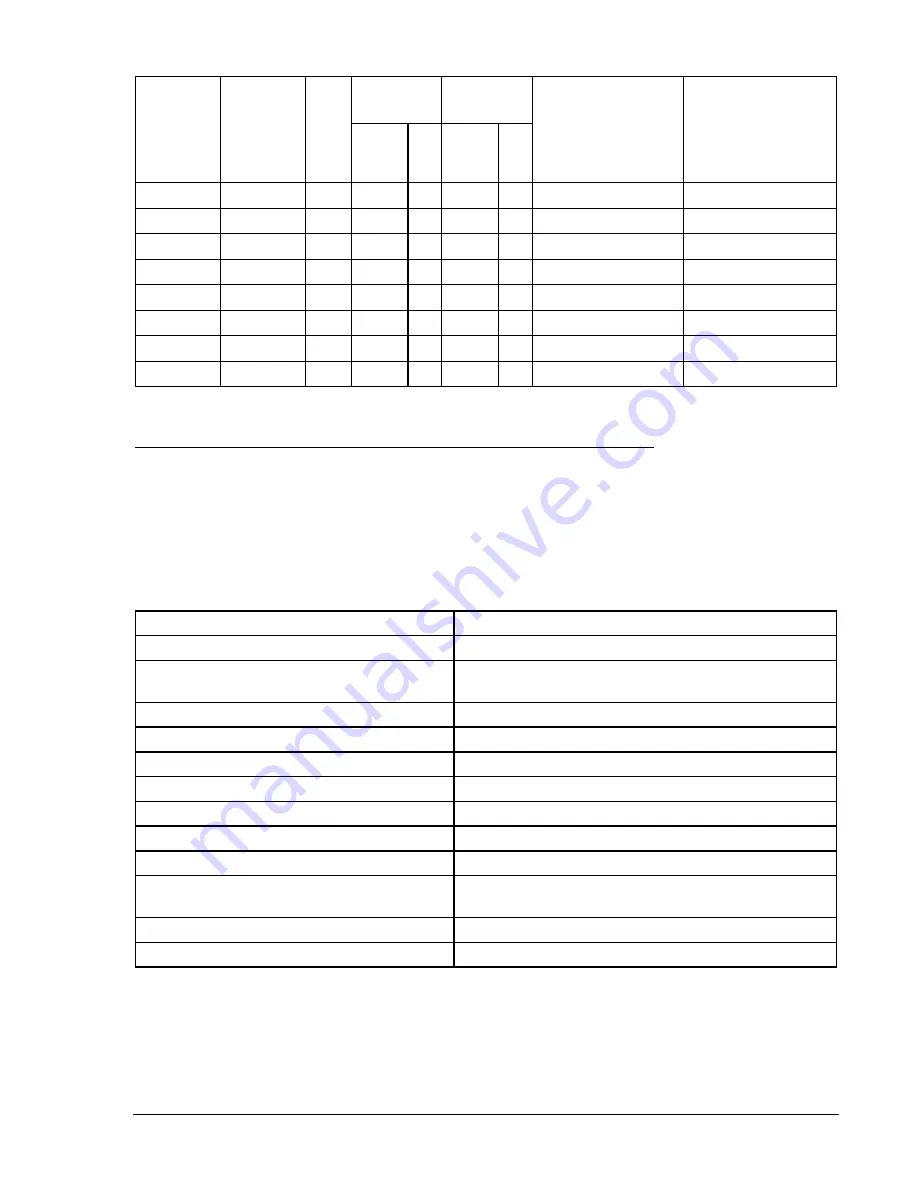

Table 13-44. Restraint Pickup Test Points (87ND – 1 Ampere Sensing Input)

Input 1

Input 2

Tap = 2.00 Tap = 3.80

Sensing

Input Type

Minimum

Pickup

Slope

(%)

Bal.

Input

(A)

PU

Bal.

Input

(A)

PU

Increasing Input 1

From Balance

Pickup (A)

Decreasing Input 2

From Balance

Pickup (A)

1 0.35

15

0.40

1

0.40

1

0.54

0.025 0.26

0.025

1 0.35

15

2.00

5

2.00

5

2.35

0.094 1.70

0.068

1 0.35

30

0.40

1

0.40

1

0.57

0.025 0.26

0.025

1 0.35

30

2.00

5

2.00

5

2.86

0.114 1.40

0.056

1 0.35

45

0.40

1

0.40

1

0.73

0.029 0.22

0.025

1 0.35

45

2.00

5

2.00

5

3.64

0.146 1.10

0.044

1 0.35

60

0.40

1

0.40

1

1.00

0.040 0.16

0.025

1 0.35

60

2.00

5

2.00

5

5.00

0.200 0.80

0.032

Instantaneous Overcurrent (50T)

Pickup and Dropout Verification (50T/150T/250T/350T/450T/550T/650T/750T)

Purpose:

To verify the accuracy of the operation of the 50T/150T/250T elements.

Reference Commands:

SL-50T/150T/250T/350T/450T/550T/650T/750T, SL-GROUP, SL-VO

Step 1:

Connect a current source to Terminals A3* and A4 (A phase Input 1).

Step 2:

To initially prepare the 50T/150T/250T/350T/450T/550T/650T/750T elements for testing,

transmit the commands in Table 13-45 to the relay.

Table 13-45. 50T/150T/250T Overcurrent Test Commands

Command Purpose

A= Gain

access.

SL-N=NONE

Zero out custom logic settings/overwrite with logic =

None settings.

Y Confirm

overwrite.

SL-N=PU50

Name custom logic for this test.

SL-50T=1,0

Enables 50TP/50TN/50TQ, CT Input 1.

SL-VO1=50TPT

Enables OUT1 to close for 50T P trip.

SL-VO2=50TNT

Enables OUT2 to close for 50T N trip.

SL-VO3=50TQT

Enables OUT3 to close for 50T Q trip.

SG-CT1=1,WYE,NA,0 Input

1

ctr = 1, ct = wye, xfmr = n/a, no ground source.

SG-TRIGGER=50TPT+

50TNT,+50TQ50TQN,0

Enable 50TP+50TN+50TQ to log and trigger fault

recording.

E Exit.

Y Save

settings.

Step 3:

Send the first appropriate row of the setting commands S0-50TP, S0-50TN, and S0-50TQ

from Table 13-46 to the relay. Using the HMI, you may also go to the front panel interface

Screen \PROT\SG0\50T\50T and edit the S0-50TP, S0-50TN and S0-50TQ settings.

Summary of Contents for BE1-CDS240

Page 2: ......

Page 8: ...vi BE1 CDS240 Introduction 9365200990 Rev F This page intentionally left blank ...

Page 38: ...1 28 BE1 CDS240 General Information 9365200990 Rev F This page intentionally left blank ...

Page 40: ...ii BE1 CDS240 Quick Start 9365200990 Rev F This page intentionally left blank ...

Page 152: ...ii BE1 CDS240 Metering 9365200990 Rev F This page intentionally left blank ...

Page 226: ...iv BE1 CDS240 Application 9365200990 Rev F This page intentionally left blank ...

Page 286: ...ii BE1 CDS240 Security 9365200990 Rev F This page intentionally left blank ...

Page 290: ...9 4 BE1 CDS240 Security 9365200990 Rev F This page intentionally left blank ...

Page 292: ...ii BE1 CDS240 Human Machine Interface 9365200990 Rev F This page intentionally left blank ...

Page 306: ...10 14 BE1 CDS240 Human Machine Interface 9365200990 Rev F This page intentionally left blank ...

Page 308: ...ii BE1 CDS240 ASCII Command Interface 9365200990 Rev F This page intentionally left blank ...

Page 342: ...11 34 BE1 CDS240 ASCII Command Interface 9365200990 Rev F This page intentionally left blank ...

Page 349: ...Figure 12 5 Horizontal Rack Mount Front View 9365200990 Rev F BE1 CDS240 Installation 12 5 ...

Page 361: ...Figure 12 17 Typical DC Connection Diagrams 9365200990 Rev F BE1 CDS240 Installation 12 17 ...

Page 372: ...12 28 BE1 CDS240 Installation 9365200990 Rev F This page intentionally left blank ...

Page 468: ...13 92 BE1 CDS240 Testing and Maintenance 9365200990 Rev F This page intentionally left blank ...

Page 512: ...14 42 BE1 CDS240 BESTCOMS Software 9365200990 Rev F This page intentionally left blank ...

Page 544: ...ii BE1 CDS240 Terminal Communication 9365200990 Rev F This page intentionally left blank ...

Page 550: ...ii BE1 CDS240 Settings Calculations 9365200990 Rev F This page intentionally left blank ...

Page 578: ...D 28 BE1 CDS240 Settings Calculations 9365200990 Rev F This page intentionally left blank ...

Page 579: ......