Configuring the Camera

Basler L301kc

4-29

DRAFT

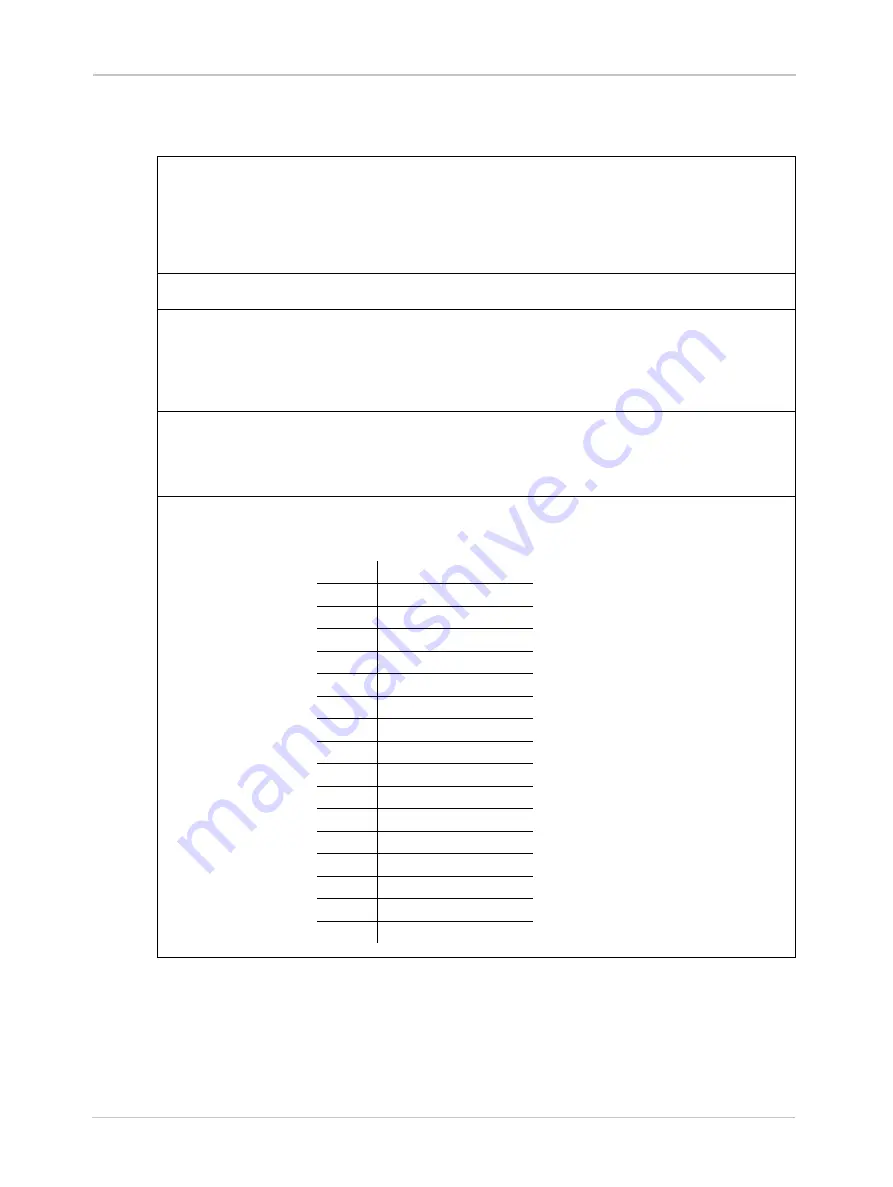

4.2.8.3 Select the Startup Pointer

Purpose:

The Startup Pointer is used to tag the configuration set that will be copied into the Work Set

at power on (see Section

).

The write command is used to set the Startup Pointer to the Factory Set or to one of the User

Sets.

The read command returns the Set ID for the current setting.

Type:

This is a read or write command.

Read Command:

Cmd-ID

R/W-Flag

Data Length

Data

0x47

1

1

-

Response:

Cmd-ID

R/W-Flag

Data Length

Data

0x47

0

1

1 Byte

Write Command:

Cmd-ID

R/W-Flag

Data Length

Data

0x47

0

1

1 Byte

Response:

None

Data Format:

Byte 1

An ID that specifies the set.

(see the table below).

Set ID

Set

0x00

Factory Set

0x01

User Set 1

0x02

User Set 2

0x03

User Set 3

0x04

User Set 4

0x05

User Set 5

0x06

User Set 6

0x07

User Set 7

0x08

User Set 8

0x09

User Set 9

0x0A

User Set 10

0x0B

User Set 11

0x0C

User Set 12

0x0D

User Set 13

0x0E

User Set 14

0x0F

User Set 15

Summary of Contents for L301kc

Page 1: ...Basler L301kc USER S MANUAL Document Number DA00051806 Release Date 13 July 2007...

Page 4: ......

Page 14: ...Introduction 1 6 Baslert L301kc DRAFT...

Page 20: ...Camera Interface 2 6 Basler L301kc DRAFT Figure 2 3 Camera Frame Grabber Interface...

Page 102: ...Configuring the Camera 4 32 Basler L301kc DRAFT...

Page 116: ...Troubleshooting 6 10 Basler L301kc DRAFT...

Page 118: ...Revision History ii Basler L301kc DRAFT...

Page 120: ...Feedback iv Basler L301kc DRAFT...

Page 124: ...Index viii Basler L301kc DRAFT...