14

15

28

# R811-0010

Remote Control Receiver

with Fobs

Remote Key Fobs

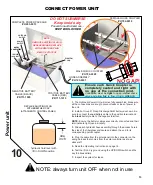

POWER UNIT

ASSEMBLY

#

H603-0012

Please order replacement parts by PART NO. and DESCRIPTION

pre-wired

with wiring

harness

Hydraulic Fluid (quart)

CONTROL PANEL

ASSEMBLY

#

R815-0008

BATTERY SAFETY IS IMPORTANT

Follow all battery manufacturer’s

warnings and safety information.

Padlock

not included

SOLAR PANEL ASSEMBLY

#

R281-0004

ENCLOSURE

#

C243-0003

# R812-0012

# Y354-0001

POWER SYSTEM COMPONENTS

# R283-0002

Solar Controller

Connect to Solar Panel

Connected

pre-charged with

hydraulic fluid

Hydraulic Cylinder Assembly

#H310-0001

(Item GG on pg 5)

Hose Assembly

#H123-0037

Hydraulic Fittings

#H711-0002

NOTE:

REMOVE SHIPPING PLUG IN

RESERVOIR AND REPLACE

WITH BREATHER PLUG

BEFORE START-UP

NOTE:

REMOVE SHIPPING PLUG IN

RESERVOIR AND REPLACE

WITH BREATHER PLUG

BEFORE START-UP

11

Q

T

Y

4

:

1

/4

x

1

.7

5

”

b

o

lt

s

("

1

5

")

Q

T

Y

4

:

1

/4

lo

c

k

w

a

s

h

e

rs

("

1

6

")

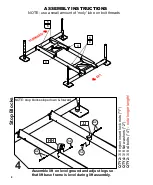

NOTE: use a small amount of 'moly' lube on bolt threads

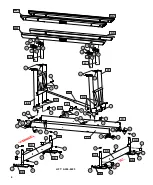

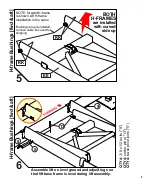

ASSEMBLY INSTRUCTIONS

11

11

Assemble lift on level ground and adjust legs so

that lift base frame is level during lift assembly.

B

u

n

k

R

a

il

A

s

s

e

m

b

ly

raise lift to install 1/4 x 1.75” bolts ("15")

15+16

15+16

NN

MM

15+16

15+16