FOR ASSISTANCE OR SERVICE:

Contact your local dealer or call

1-866-Go-Basta

or email: service@gobasta.com

BATTERY

Always use AGM batteries and follow battery

manufacturer’s warnings and instructions. Improper

use, or use of other batteries, have the potential

to produce flammable hydrogen gas which can

result in serious injury or death. If you have limited

solar exposure when the lift is not in use (typically

winter), consider moving battery to a temperate

environment (garage) and leave on battery

maintainer.

SOLAR PANEL

Every Month (more as needed)

Wipe the solar panel with a clean, damp cloth to

maintain its charging performance

IMPORTANT

ONLY ADD FLUID WITH LIFT IN

DOWN POSITION

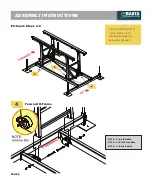

Hydraulic fluid shown with lift

in the DOWN position

one

inch

1”

EVERY 6 MONTHS, WE RECOMMEND:

. Inspect hoses, cylinders and fittings for leaks and

wear

. Check wire terminals for snugness and corrosion

. Check hydraulic fluid level and clarity. The

hydraulic fluid level should be about one inch below

the top of the reservoir with the lift completely

down. DO NOT add fluid with the lift in the raised

position! Use only Basta Boatlifts approved fluid.

The lift power system does not consume fluid, so if

fluid is low, look for leaks

EVERY 3-5 YEARS, DEPENDING ON US-

AGE:

Flush hydraulic fluid. Visit the Basta Boatlifts

service page for detailed instructions on how to

perform a fluid flush. https://bastaboatlifts.com/

support/.

Annual factory approved service is available.

Contact your local dealer or Basta Boatlifts for

additional information.

PAGE 19

MAINTENANCE