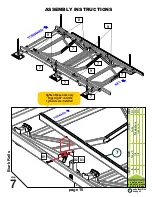

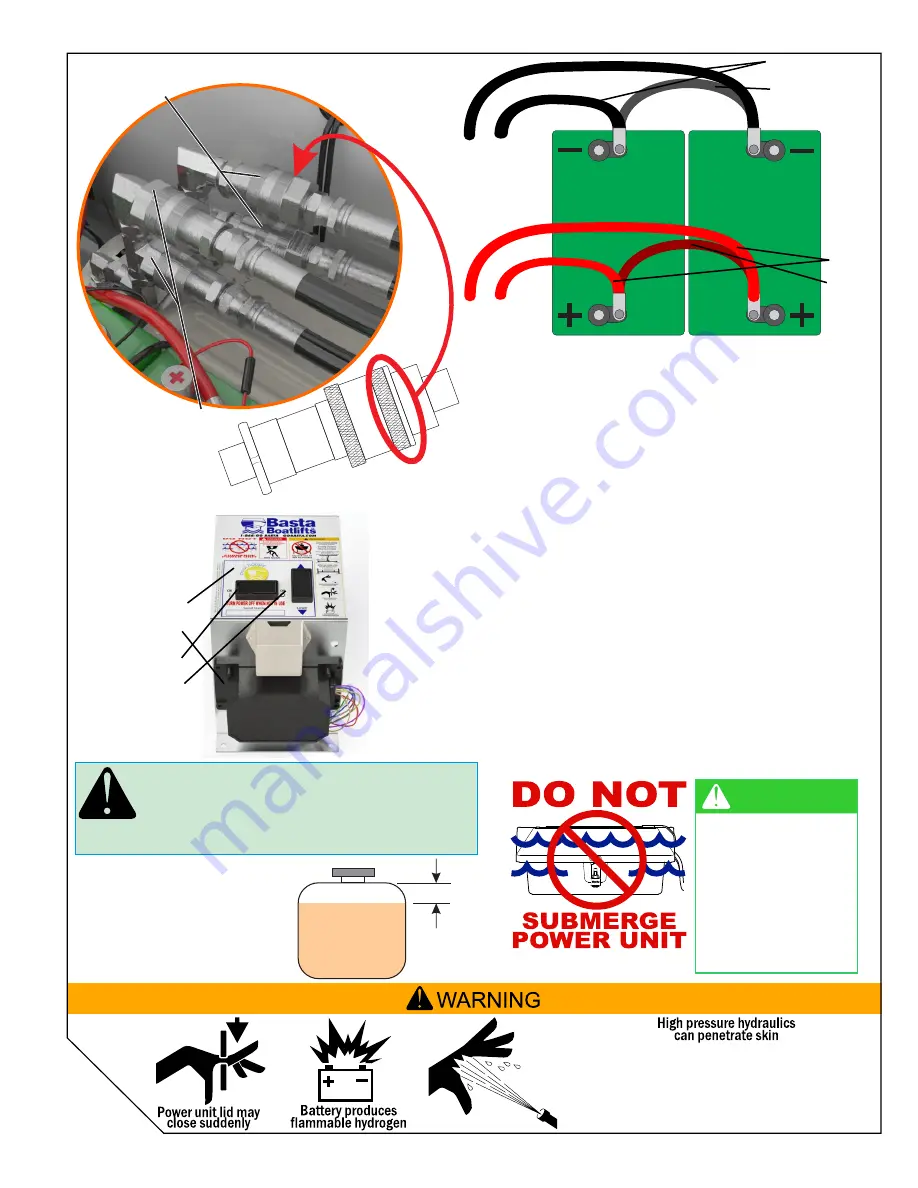

NO GAP!

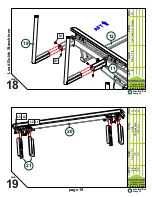

4

5

4.

Test the lift on dry ground using the Up/Down Switch

( # 9) and the Key Fob Transmitters. Inspect the

system for leaks.

1.

The Hydraulic Pump will arrive fully assembled. Make

s u re all the connections are snug to prevent leaks or

loss of power to the unit.

2.

Install two Group 31 Marine Grade Batteries as shown

a b ove.

Confirm that the POWER switch on the Control

Panel (#8) is OFF.

Connect solar panel to the

solar controller (see page 15).

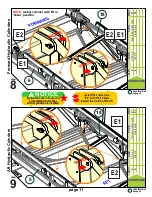

Connect the Black Link Cable (#19) between the two negative

terminals of the batteries. Connect the Red Link Cable (#21)

between the two positive terminals of the batteries. Connect

the Red Battery Cables (#13) to the positive terminals and the

Black Battery Cables (#12) to the negative terminals of the

battery bank as shown.

NOTE:

Ensure battery cables are correctly connected

and their terminals are very tight (otherwise there is

a risk of overheating).

3.

Slide the Hydraulic Cylinder Hoses through the

a

c cess holes in the side of the White Fiberglass Box

(#10) and attach them to their corresponding

Quick Couplers (#4, #5).

Ensure each Quick Coupler is

completely seated and

tight

with

no gap at the connection joint.

Connection must be

tight

to open internal

check valve and allow fluid to flow. USE PLIERS

one

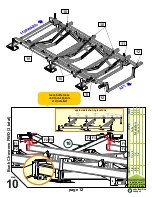

inch

hydraulic fluid level with

lift in DOWN position

only add fluid with lift

in DOWN position

H

y

d

ra

u

li

c

P

o

w

e

r

U

n

it

17

page 17

step

OIL INJECTED INTO THE SKIN FROM HIGH PRESSURE

LEAKS IN HYDRAULIC SYSTEMS CAN CAUSE SEVERE

INJURY. MOST DAMAGE OCCURS DURING THE FIRST

FEW HOURS. SEEK MEDICAL ATTENTION IMMEDIATELY.

SURGICAL REMOVAL OF OIL MAY BE NECESSARY.

Keep inside dry

Tighten nuts on

batteries very tight.

Otherwise, cables

may overheat

during lift

operation.

NOTICE

Battery

Group 31

marine

deep cycle

Battery

Group 31

marine

deep cycle

Battery

Battery

Battery

Battery

6

7

8

9

12

13

19

21

NOTE:

pump

appearance

may vary