4

GG

MM

MM

MM

MM

CC

FF

EE

CC

HH

HH

LL

LL

LL

DD

AA

AA

AA

AA

BB

BB

BB

BB

DD

7&2

1&2

9

7&2

1&2

9

7&2

1&2

7&2

7&2

1&2

9

9

7&2

1&2

7&2

1&2

1&2

7&2

5

5

4

4

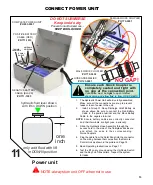

11&2

4

5

5

4

11&2

19

19

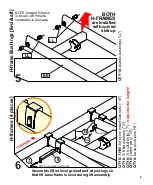

6

14

8

15

15

17&18

15

17&18

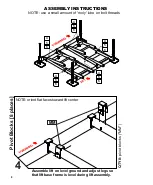

3

8

15

13

13

13

13

16

16

16

16

17&18

17&18

17&18

10

10

10

10

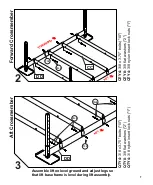

KK

JJ

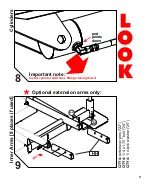

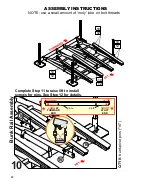

ONLY ONE

LIFT SHOWN

FOR CLARITY

OPTIONAL

5

(8 )

MECHANISM PARTS LIST

SEE PAGES 14-15 FOR ELECTRICAL AND HYDRAULIC PARTS

ITEM

PART NO.

DESCRIPTION

QTY.

JJ

HH

A427-0014

W102-0045

Bunk Rail Assembly, Left

H-frame Arm, Inner

2

8*

KK

A427-0015

Bunk Rail Assembly, Right

2

LL

W410-0067

Bunk Board Assembly (part of JJ, KK)

(4)

MM

NN

N/A

M621-1002

K200-0127

Base Pivot Bushing

Pivot Block

16

8

ITEM

PART NO.

DESCRIPTION

QTY.

AA

BB

CC

DD

EE

FF

GG

K200-0125

W117-0001

W105-0012

W111-0019

A431-0040

A431-0039

SEE PG. 14

Leg

Foot Pad

Side Rail

Base Crossmember

H-frame, Forward

H-frame, Aft

Hydraulic Cylinder

4

4

4

2

2

2

2

ITEM

PART NO.

DESCRIPTION

QTY.

Y356-0003

anti-seize grease packet

2

S532-1801

P pin SS

4

14

S503-0010

bunk pin SS

8

15

16

S362-0108

nut, 3/8-16 nylock thin SS

8

17

18

F730-0021

plastic cap for 2" ID sq tube

4

19

S503-0016

clevis pin, 3/4 x 3.5 SS

2

20

S503-0011

extension pin SS

0

21

22

23

24

25

S103-0705

S103-0338

S322-0006

bolt, hex head 1/4-20 x 1.75 full thread SS

bolt, hex head 1/2-13 x 1.0 SS

washer, lock 1/4 SS

4

8

8

ITEM

PART NO.

DESCRIPTION

QTY.

1

2

3

4

5

6

7

8

9

10

11

12

13

S362-0008

S313-0008

S313-0007

S322-0007

S342-0007

S503-0015

S103-0515

S503-0012

S314-0032

S103-0516

S522-0801

S520-1706

nut, 3/8-16 nylock SS

washer, flat 3/8 SS

washer, flat 5/16 SS

washer, lock 5/16 SS

nut, 5/16-18 SS

clevis pin 3/4 x 5.0 SS

bolt, hex head 3/8 - 16 x 3-1/2 SS

base pivot pin SS

washer, flat 3/4 nylon

bolt, hex head 3/8 - 16 x 3-3/4 SS

ring cotter pin 3/4 x .091 SS

cotter pin 3/16 x 2.0 SS

12

32

12

12

12

2

8

8

4

12

4

8

(8 )

(16 )

(16 )

QUANTITIES INCLUDED WITH

OPTIONAL EXTENSION ARMS

20

13

25

24

16

3

11

5

4

23

15

8

10

14

22

7

2

18

6

9

2

2

1

21

17&18

17&18

17&18

10

KK