Installation & Maintenance Manual: BRBAC 1 HP

Published December 2019

Rev.A1

32

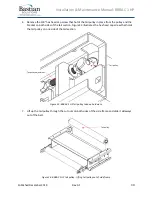

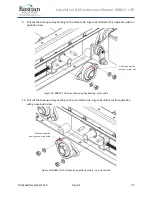

Figure 25: BRBAC 1 HP drive motor connection - exploded view

ZiPline Conveyor highly recommends using a lift table or equivalent equipment to

remove the motor from the drive section. Improper handling of the motor can cause

damage and increase risk of injury.

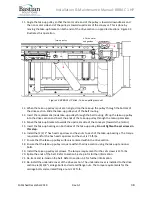

7.

Remove the underside cover closest to the drive pulley from the drive section. The underside

cover closest to the drive pulley is attached by (4) 3/8” carriage bolts and serrated flange nuts

and (4) 1/4

” hex head cap screws and clip on nuts.

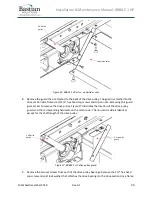

Figure 26 illustrates the location of the

underside cover and corresponding hardware on the motor side. The non-motor side is identical

except for the shaft length of the drive pulley.

AC drive motor

and gearbox

1 HP drive

pulley

7/16” hex head

cap screw

M8 shoulder bolt

Torque arm

Summary of Contents for BRBAC 1 HP

Page 1: ...Installation and Maintenance Manual Model BRBAC 1 HP Effective December 2019 Rev A1...

Page 44: ...Installation Maintenance Manual BRBAC 1 HP Published December 2019 Rev A1 44...

Page 45: ...Installation Maintenance Manual BRBAC 1 HP Published December 2019 Rev A1 45...

Page 46: ...Installation Maintenance Manual BRBAC 1 HP Published December 2019 Rev A1 46...

Page 47: ...Installation Maintenance Manual BRBAC 1 HP Published December 2019 Rev A1 47...