English

8

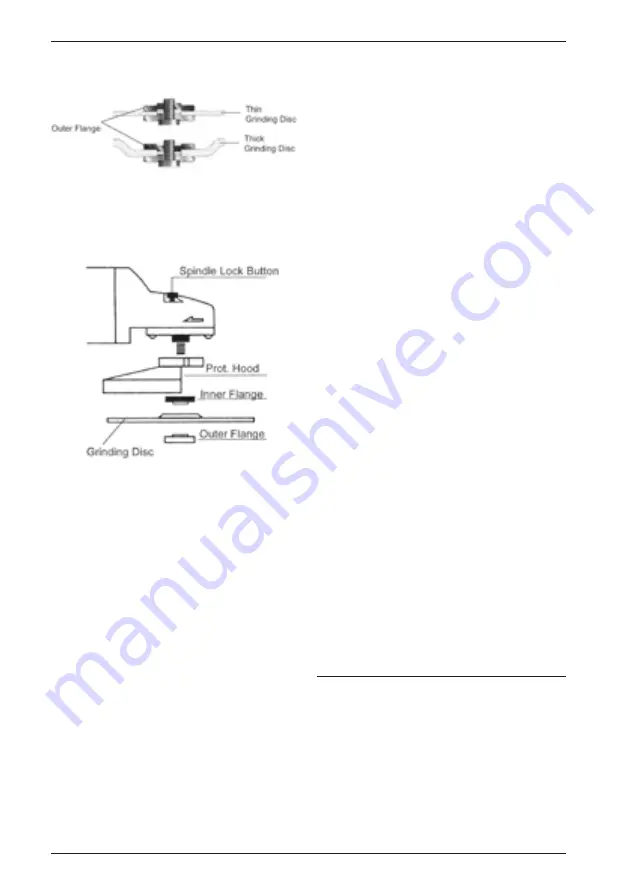

7. The outer flange has two different sides.

Screw the outer flange on the spindle as

follows:

If you are using thin grinding discs, screw the

outer flange upwards with the collar. If you are

using thick grinding discs, screw the outer

flange downwards with the collar.

8. Spin the grinding disc by hand to check

for proper installation and ease of

movement.

9. Perform a test run (see Startup).

10. To change the grinding disc, go in reverse

order after you have loosened the outer

flange using the face pin wrench. Before

changing the grinding disc, clean the outer

flange and the inner flanges from grinding

residue each time.

Startup

1. To turn on the device, hold down the

safety switch

(7)

and then press the ON/

OFF switch

(8)

.

2. Release the ON/OFF switch

(8)

and the

device turns off.

Deburring (Fig. D)

An angle of inclination of 30º to 40º will give the

best results when deburring. Move the

machine back and forth using light pressure.

This will prevent the work piece from discolour-

ing or becoming too hot and will avoid making

groves.

Never use abrasive cutting discs for deburring

work!

Cutting (Fig. D)

For cutting, a special protection guard must be

used (not included).

Maintain firm contact with the work piece to

prevent vibration and do not tilt or apply pres-

sure and when cutting. Use moderate pressure

when working, appropriate to the material that

is being worked on. Do not slow down wheel

discs by applying sideways counter pressure.

The direction in which you want to cut is

important.

The machine must always work against the

direction of the cut; so never move the

machine in the other direction! There is the risk

that the machine will catch in the cut causing

kickback and that you will lose control.

Hints for optimum use

• Clamp the work piece. Use a clamping

device for small work pieces.

• Hold the machine with both hands.

• Switch on the machine.

• Wait until the machine has reached full

speed.

• Place the wheel disc on the work piece.

• Slowly move the machine along the work

piece, firmly pressing the wheel disc

against the work piece.

• Do not apply too much pressure on the

machine. Let the machine do the work.

• Switch off the machine and wait for the

machine to come to a complete standstill

before putting the machine down.

MAINTENANCE AND CLEANING

WARNING:

Always disconnect from the mains

power supply, before carrying out any mainte-

nance/ cleaning of the charger. Remove the

battery before carrying out any maintenance/

cleaning of the tool.

Maintenance

There are no inner parts of the tool which need

maintenance.