ImVT 120 II Mini Verticus

Page 10

1st Edition, Rev. 0 Chg. 10

2.7.2

Two Flashes - Securus Monitor (Optional)

The compressor purification system may be equipped with an optional Securus

®

Electronic Moisture

Monitor. This consists of a control module and cable connected to the purification chamber. It functions

as a capacitive sensor, sensing the moisture in the purified air. When the chemicals in the purification

cartridges have reached the point where they retain a set level of moisture, the Securus

®

monitor will

issue a warning via the amber Warning Light. On a Securus

®

Warning condition, the compressor will

run normally, the PLC I7 lamp will illuminate, and the warning code will flash. This warning is meant

to prompt the operator to schedule replacement of the purification cartridge.

2.8

Alarms

The red Warning Light located on the control panel flashes warning codes with a 0.5 second on, 0.5

second off sequence with a distinct pause between sequences.In addition the light will illuminate on ini-

tial start up for a period of 5 seconds, to serve as a lamp test function. The lamp is a LED lamp for long

trouble free life.

2.8.1

One Flash - Compressor High Temperature

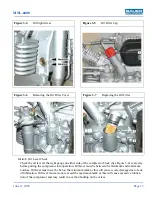

The compressor high temperature switch is located on the compressor block, third, fourth or fifth stage

head, depending on model. Under normal operating conditions, the switch is closed and the I1 lamp on

the PLC is illuminated. On a high temperature condition, the compressor will shutdown, the I1 lamp

will extinguish, and the alarm code will flash.

2.8.2

Two Flashes - Compressor Low Oil Pressure

The compressor oil pressure switch is located on the back of the compressor block, mounted with the

oil pressure gauge. The switch is N.O., Normally Open, and is connected to the PLC on terminal I2.

During startup of the compressor, the oil pressure switch is bypassed for a period of 45 seconds to allow

the oil pressure to stabilize, then the switch will close. Then should the compressor lose oil pressure, the

compressor will shutdown, the I2 lamp will extinguish, and the alarm code will flash.

2.8.3

Three Flashes - Compressor Overtime

The compressor has an overtime function, where if the compressor runs continuously for 5 hours, then

the compressor will shutdown, and the alarm code will flash. This is done to secure the equipment if it

were to be started and left unattended.

2.8.4

Four Flashes - Securus Monitor

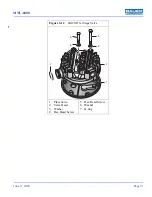

The compressor purification system is equipped with a Securus

®

Electronic Moisture Monitor. This

consists of a control module and cable connected to the purification chamber. It functions as a capaci-

tive sensor, sensing the moisture in the purified air. When the chemicals in the purification cartridge has

reached the point where it retains a set level of moisture, the Securus

®

monitor will issue an alarm via

the red Alarm Light. On a Securus

®

ALARM condition, the compressor will shutdown, the PLC I5

lamp will be illuminated, and the alarm code will flash.

^

WARNING

Do not attempt to override the Separator Shutdown Warning.

This feature is provided to protect personnel from injury or death.