MNL-0408

June 11, 2009

Page 13

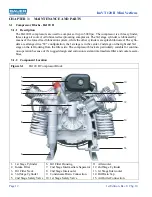

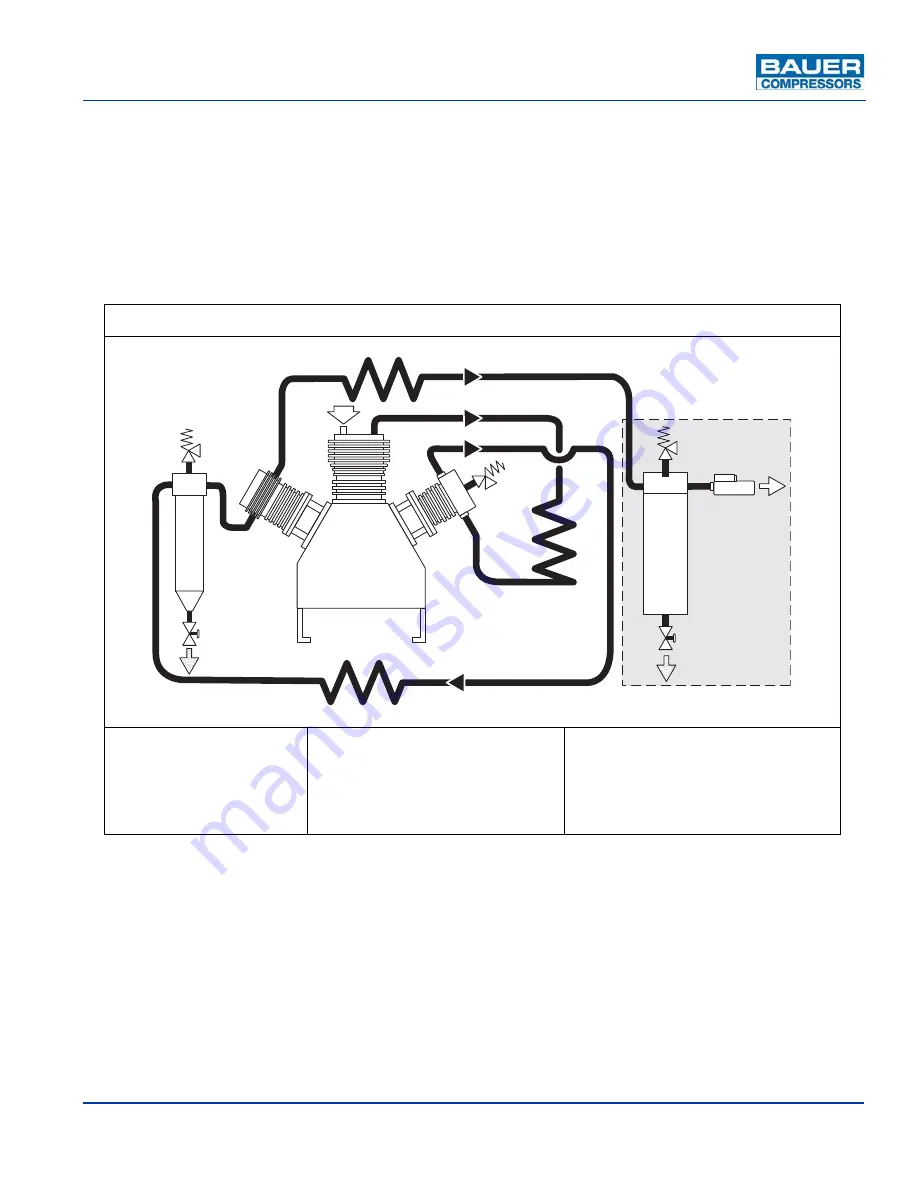

3.1.3

Air Flow Diagram

Refer to Figure 3-2. The air is drawn in through intake filter (1), compressed to the final pressure in cyl-

inders (2, 3, 4,) and cooled by intercoolers (5, 6) and aftercooler (7). The safety valves (8,9, 10) protect

from overpressure in the individual stages. The compressed air is filtered by intermediate separator (11)

and oil and water separator assembly (12). The intermediate separator (11) and oil and water separator

(12) are drained by condensate valves (14). An Automatic Condensate Drain system is available as an

option. The pressure maintaining valve (13) ensures that pressure is built up in the purification system

from the start of delivery, thus achieving constant optimum purification. The parts in the shaded box are

part of the Purification System which may be a factory installed option.

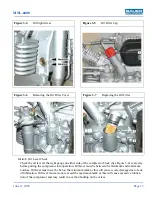

3.1.4

Compressor Lubrication

3.1.4.1

Description

Refer to Figure 3-3. The compressor is provided with forced-feed lubrication. The oil pressure is pro-

duced by a low speed gear pump (1). The oil pressure is approximately 73 psi (5 bar).

The oil pump (1) is coupled to and driven by the crankshaft. It pumps oil through the oil line filter (2)

and a minimum pressure valve (3) to the 3rd stage cylinder. The oil is then distributed by the guide pis-

ton (4) of the 3rd stage and lubricates all the moving parts of the compressor block.

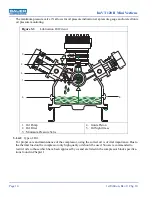

Figure 3-2

Air Flow Diagram

1. Intake Manifold

2. 1st Stage Cylinder

3. 2nd Stage Cylinder

4. 3rd Stage Cylinder

5. 1st Stage Intercooler

6. 2nd Stage Intercooler

7. 3rd Stage Aftercooler

8. 1st Stage Safety Valve

9. 2nd Stage Safety Valve

10. Final Pressure Safety Valve

11. Intermediate Separator

12. Oil and Water Separator

13. Pressure Maintaining Valve

14. Manual Condensate Drain Valve

14

11

4

9

2

1

3

8

5

14

12

Purification

System

13

10

6

7