ImVT 120 II Mini Verticus

Page 54

1st Edition, Rev. 0 Chg. 10

CHAPTER 4: IK120 II MAINTENANCE SCHEDULE

4.1

IK120 II Maintenance Intervals

4.1.1

Maintenance Records

We recommend that all maintenance work be recorded, showing the date and details of the work carried

out. This will help to avoid expensive repairs caused by missed maintenance work. If it is necessary to

make a claim against the warranty, it will help to have proof that regular maintenance has been carried out

and that the damage has not been caused by insufficient maintenance.

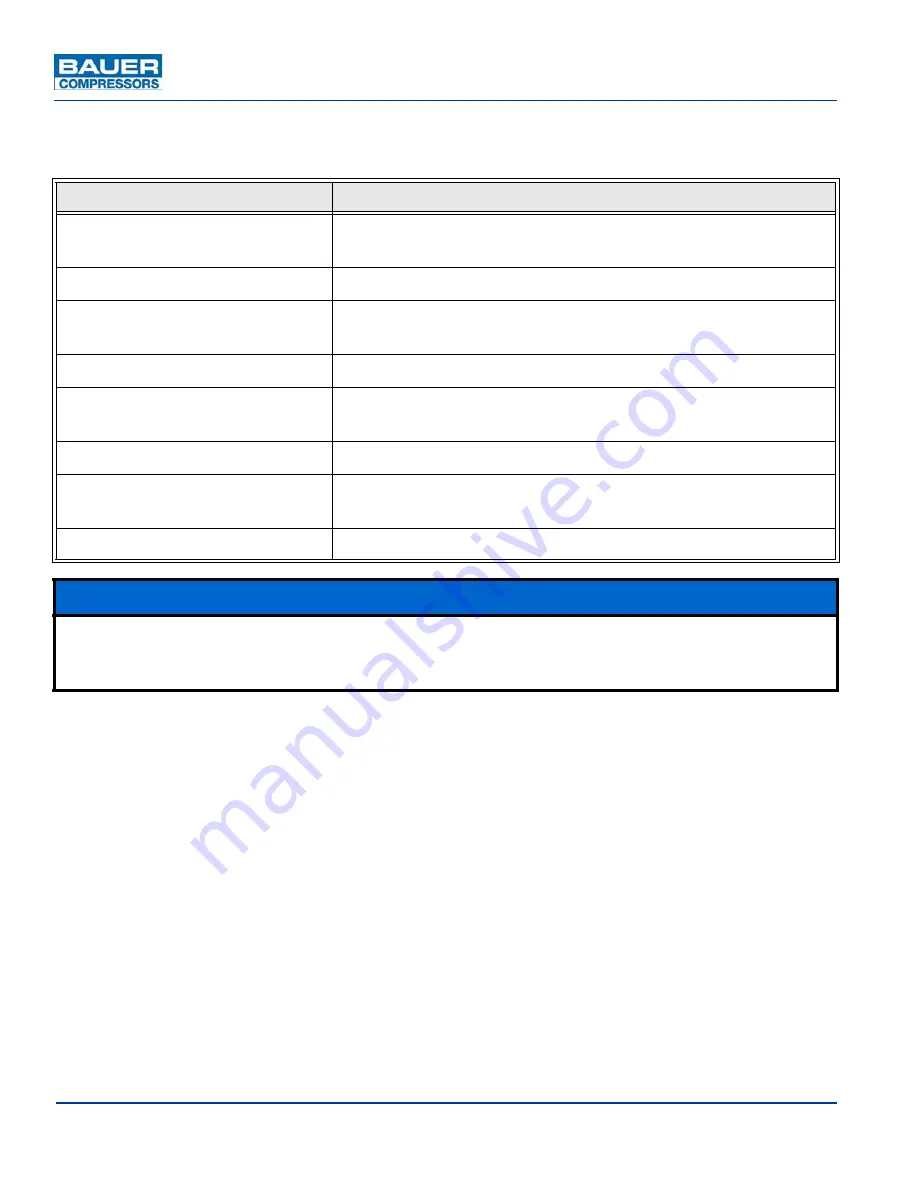

Interval

Maintenance Work

Daily before operating unit

Check Oil Level

Operate unit to final pressure and check final pressure switch

½ hour after maintenance work

Check screws and fittings for tightness

500 operating hours

Service micronic intake filter

Check all connections for leakage

1,000 operating hours

Valve Check

2,000 operating hours

Change Synthetic Oil and Change Oil Filter

Replace Valves

3,000 operating hours

Check pistons and piston rings

Annually

Check opening pressure of final safety valve.

Service micronic intake filter

Biennially

Change Synthetic Oil, if operated for less than 2,000 hours

NOTICE

All maintenance intervals refer to normal operating conditions. Operating the compressor under extreme

conditions like high temperatures, humidity or continuous operation may shorten the intervals signifi-

cantly. If in doubt, please contact the Bauer service department.