ImVT 120 II Mini Verticus

Page 18

1st Edition, Rev. 0 Chg. 10

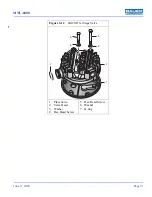

3.1.7

Intermediate Separator

An intermediate separator is mounted on the compressor between the 2nd and 3rd stage. This separator

is designed to remove oil and water which accumulates due to the cooling of the medium after the com-

pression process. Separation is achieved by means of centrifugal action provided by a vortex plate (1)

3.1.7.1

Maintenance

The Intermediate Separator P/N 081799 requires no maintenance.

Figure 3-9

Intermediate Separator

1. Vortex Plate

2. Hollow Screw

3. Center Insert

4. O-ring

5. Knurled Nut

6. Gasket

7. Fitting

8. Safety Valve

^

WARNING

The rapid depressurizing and repressurizing of the intermediate separator during condensate draining sub-

jects it to metallurgical stresses. To prevent catastrophic failure with the possibility of damage, injury or

death the intermediate separator must be replaced after 85,000 load cycles. A load cycle equals one

depressurization- repressurization. The Bauer recommended frequency of condensate draining is every

fifteen minutes and is a balance between maximizing the life of the oil and water separator chamber and

maintaining the quality of the delivered air.

1

2

3

4

5

6

7

8