ImVT 120 II Mini Verticus

Page 52

1st Edition, Rev. 0 Chg. 10

3.3

Condensate Collector

During compression the water content of the air is also compressed. The resulting water is removed

after each compression stage and is collected through the automatic condensate drain system.

This water, additionally, has a small oil content. The separation of oil and water is not possible through

simple methods; therefore the condensate has to be completely removed. It is most practical to collect

this condensate in special containers and dispose of it entirely.

For these compressor units a metal housing and tank assembly is used. A float level switch is also

included. The condensate is drained from the tank assembly by the manual drain valve into a separate

container for proper disposal.

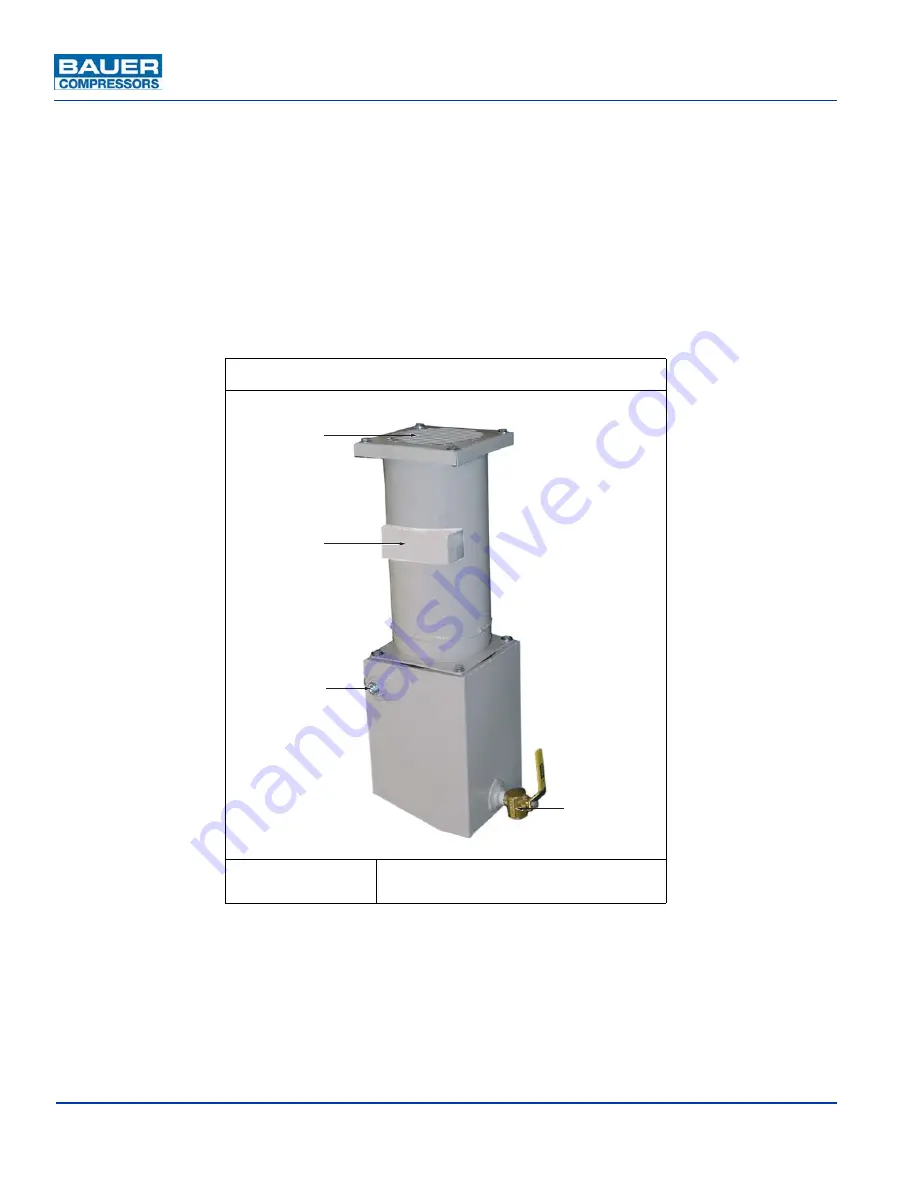

Figure 3-36

Condensate Collector

1. Air Discharge

2. ACD Manifold

3. Float Level Switch (opposite side)

4. Manual Drain Valve

1

2

3

4