Page 8

For technical questions, please call 1-888-866-5797.

Item 56401

S

AFE

ty

Op

ERA

ti

O

n

M

A

int

E

n

A

n

CE

S

E

t

U

p

Specifications

Battery Type

Bauer 20V Li-ion:

64816 (sold separately)

Charger Type

Bauer 20V Li-ion:

63947 (sold separately)

No Load Speed

n

0

: 7000/min

Spindle Thread

5/8

″

–

11 UNC

Wheel Diameter

4-1/2

″

Setup - Before Use:

Read the EntiRE iMpORtAnt SAFEty inFORMAtiOn section at the beginning of this

manual including all text under subheadings therein before set up or use of this product.

tO pREVEnt SERiOUS inJURy FROM ACCiDEntAL OpERAtiOn:

Make sure that the trigger Switch is in the off-position and remove the

Battery pack before performing any procedure in this section.

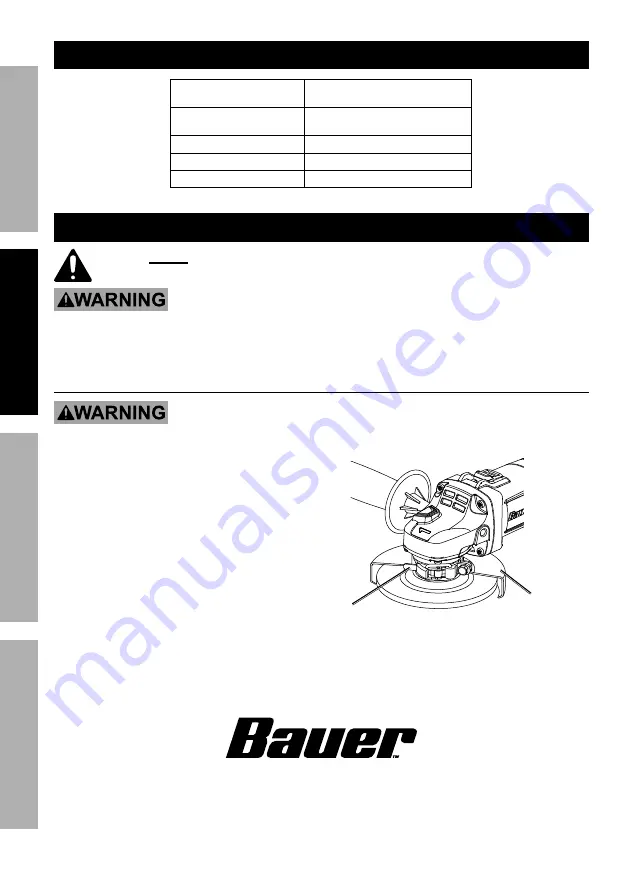

installing the Wheel Guard

tO pREVEnt SERiOUS inJURy: Do not operate this tool without the Wheel Guard properly installed.

1. Pull the Clamp Handle out, away from the

Grinder, to unlock and loosen the Wheel Guard.

2. Slide the collar of the Wheel Guard

over the rim of the Gear Housing.

3. Rotate the Wheel Guard as needed to

shield you during the planned work.

4. Once positioned, push to close and

lock the Clamp Handle in place.

5. Check the Wheel Guard to ensure

it is firmly in place. Adjust if

necessary before proceeding.

Wheel Guard

Clamp Handle