Page 8

For technical questions, please call 1-888-866-5797.

Item 58253

SA

FE

TY

OP

ERA

TI

O

N

MAINT

ENANC

E

SE

TUP

Operating Instructions

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this

manual including all text under subheadings therein before set up or use of this product.

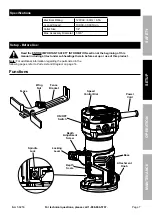

Tool Set Up

TO PREVENT SERIOUS INJURY FROM ACCIDENTAL OPERATION:

Make sure that the Power Switch is in the off-position and unplug the tool from

its electrical outlet before performing any procedure in this section.

Installing the Router Bit

Note:

This tool includes a 1/4

″

collet. Use

only bits that have a 1/4

″

shank.

Note:

Do not use a bit with a cutting diameter

larger than the opening in the base.

1. Use only bits that are marked as suitable

for the type of material being cut.

2. Use only bits that are marked with a speed equal

or higher than the speed marked on the tool.

3. Unplug the Router from the electrical outlet.

4. Release the Locking Lever and use the

Depth Adjustment Screw to move the

Base down to expose the Collet Nut.

5. Press the Spindle Lock in to keep

the Spindle from turning.

6. Using the Large Wrench included, loosen

the Collet Nut, but do not remove.

7. If there is already a bit in the Collet, remove it.

8. Push the shank end of the new bit (sold

separately) into the opening in the Collet

Nut. There may be some resistance, so

make sure that it goes in all the way.

9. Pull out bit slightly so that there is

1/16

″

gap at bottom of bit.

10. While holding in the Spindle Lock, tighten

the Collet Nut with the Large Wrench.

Adjusting Cutting Depth

Set the depth of cut using the scale

marked on the side of the Router.

1. Install the router bit as previously described.

2. Unplug Router from electrical outlet

before making any adjustments.

3. Release the Locking Lever and use the Depth

Adjustment Screw to move the Base down so

the router bit is retracted within the Base.

4. Place the Base on a flat surface, and

slide the Router down in the Base

until the tip of the bit contacts the work

surface. Tighten the Locking Lever.

5. The depth scale on the Housing now shows

the starting position. This starting position

will vary depending on the bit used.

6. Add the desired depth of cut to the starting position.

For example, if the starting position is 1/2"

and the desired depth of cut is 1/4", the

correct adjustment on the scale is 3/4".

7. Release the Locking Lever, and use the Depth

Adjustment Screw to move the Housing up

until the scale shows the correct reading;

in this example 3/4". Tighten the Locking Lever.

8. Make a test cut on a piece of scrap material

to ensure that the adjustment is correct.