Page 11

For technical questions, please call 1-888-866-5797.

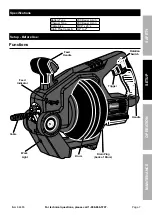

Item 64483

Sa

FE

ty

Op

E

ra

ti

O

n

Maint

E

nanc

E

S

E

tup

cleaning the cable

1. Thoroughly flush Drain Cleaner Cable with

clean water after every use. Doing so will

help prevent the build-up of sediment and any

drain cleaning chemicals still in the cable.

2. Once Cable has been flushed, carefully

tip the Drain Cleaner forward to empty

out any remaining debris.

3. Rotate the Drum until the Drain Plug is visible.

4. Remove the Drain Plug and tilt the

Drain Cleaner backward to allow any

remaining fluid to drain out of the Drum.

5. Once the Cable is clean and dry,

pull the Cable from the Drum.

6. Lubricate with oily rag as you feed

Cable back into Drum.

WarninG! Do not pull a rotating cable.