34

What should I do when the automatic safety system detects a malfunction?

The programme is interrupted, an audible tone sound and various indicators (if available) point to the

source of the fault.

Fault description table

a. Water inlet fault (no or insufficient water supply)

The “Water tap” indicator is on or the display

alternately shows “H” and “F” and an audible

tone sounds. Switch off the appliance by

turning the programme selector to the

position and unplug it.

Check whether:

•

the water tap is completely open, and the

water supply pressure is sufficient;

•

the water inlet hose is kinked;

•

the mesh filters are clogged (see “Care and

Maintenance” / “Water Hose Mesh Filters”);

•

the water inlet hose is frozen;

•

the appliance has a safety hose and the

safety valve has opened (red indicator in the

safety valve inspection window); In this case

replace with a new safety hose.

Connect the appliance to the electrical outlet.

Reselect the desired programme and press

the “Start/Pause” button again to continue

with the programme (do not add detergent for

this programme)

b. Draining out fault

The display alternately shows “P” and “F” and

an audible tone sounds. Switch off the

appliance by turning the programme selector

to the

position and unplug it.

Check whether:

•

the drain hose is kinked (see “Installation

instructions”);

•

the pump / filter are blocked (see “Removing

the Filter / Draining Residual Water”).

IMPORTANT: before draining, allow the

wash water to cool down.

•

the drain hose is frozen.

Connect the appliance to the electrical outlet.

Reselect the desired programme and press

the “Start/Pause” button again to continue

with the programme (do not add detergent for

this programme).

If the fault re-occurs, contact After-Sales

Service (see “After-Sales Service”).

c. Electrical module fault

The “Spin Speed” indicator and the “Start

Delay” option are flashing and an audible tone

sounds. The display shows “F4” to “F16”.

•

Switch off the appliance. Select a

programme and press the “Start/Pause”

button once again.

The programme will continue.

•

If the fault re-occurs, contact After Sales

Service (See “After-Sales Service”).

d. Water Stop fault

An audible tone sounds. The light of the

Water Stop indication is on.

The display alternately shows “A” and “F”.

Switch off the appliance by turning the

programme selector to the

position,

unplug the appliance and make sure that the

water tap is closed.

The “Water Stop” may have been

triggered by:

1. too much foam.

2. a leak in the inlet hose or in the appliance.

Tilt the appliance forwards carefully to allow

the collected water to flow out.

Then:

1. connect the appliance to the electrical outlet,

2. open water supply to machine (if

“Start/Pause” button is not pressed, but

machine begins to fill, close water supply

and call After-Sales Service),

3. reselect the desired programme and

press the “Start/Pause” button (there is

no need to add additional detergent).

The programme will continue.

If the faults occurs again, call After-Sales

Service with details about the fault (see

“After-Sales Service”).

Fault “Water Stop” when the programme

selector is on the

position.

The appliance identifies a water leakage even

when the power is off.

An audible tone sounds. The display

alternately shows “A” and “F”.

•

The water leakage can be caused by a

leak in the inlet hose or in the appliance.

Unplug the appliance and make sure that the

water tap is closed, lean the appliance over

onto its front side to allow the collected water

to flow out.

Call After-Sales Service with details about the

fault (see “After-Sales Service”).

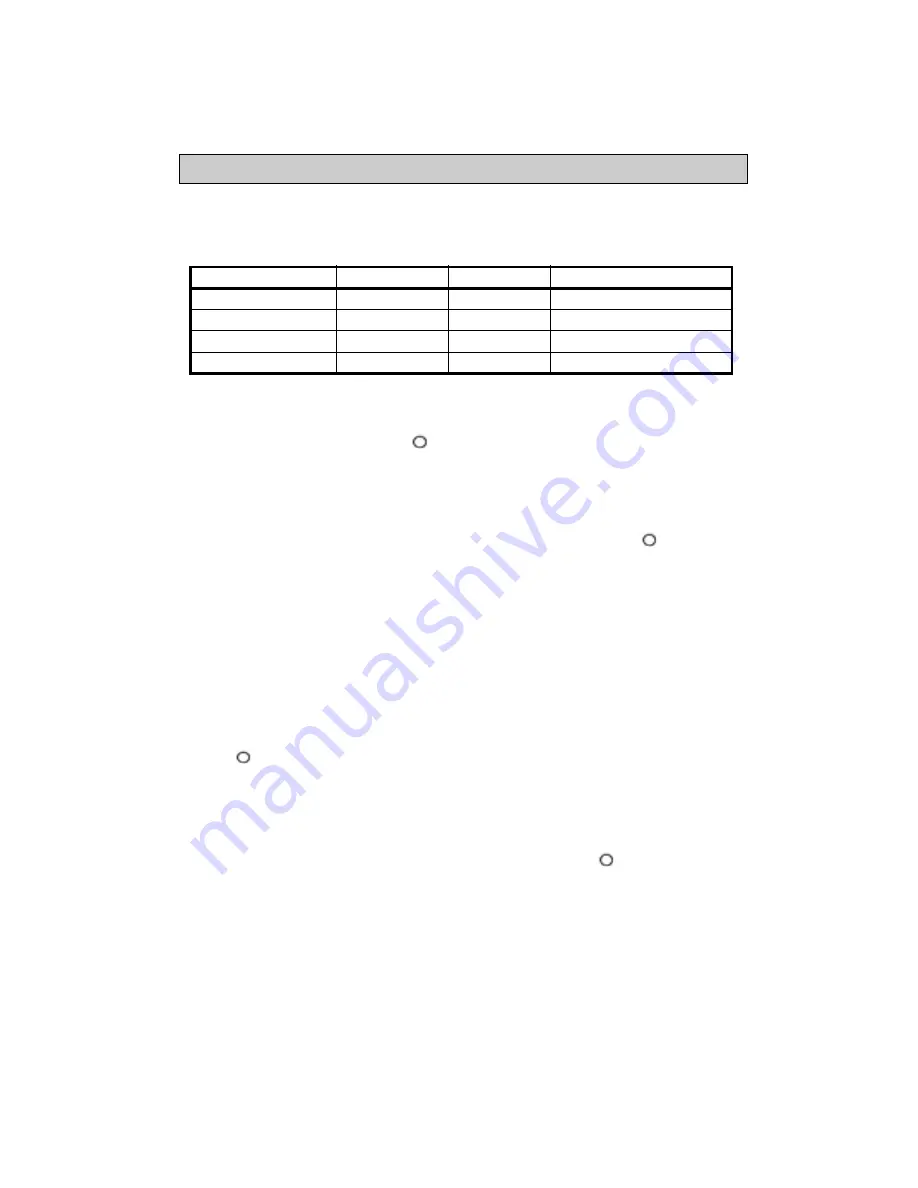

TROUBLESHOOTING GUIDE

Small lamp lights up

Digital display

Audible tone

Fault description

“Water tap”

“H” and “F”

30 sec

“Water inlet fault”

-

“P” and “F”

30 sec

“Draining fault”

-

“F4” to “F16”

30 sec

“Electrical components fault”

“Water Stop”

“A” and “F”

30 sec

“Water Stop fault”