8. STORAGE

1. Store grinder in a dry place.

2. Clean grinder thoroughly. Dirt and wood chips

will draw moisture and cause rust.

3. Lubricate machine. (See Service and

Maintenance section.)

4. Check condition of cutting teeth. Replace as

necessary. (See Service and Maintenance

section.)

5. Check for loose or missing hardware.

6. Paint parts as necessary.

7. Store PTO driveshaft off the ground.

8.2 Remove From Storage

1. Review Operator’s manual and check

adjustments.

2. Lubricate machine. (See Service and

Maintenance section.)

3. If parts have been replaced, verify they run

properly.

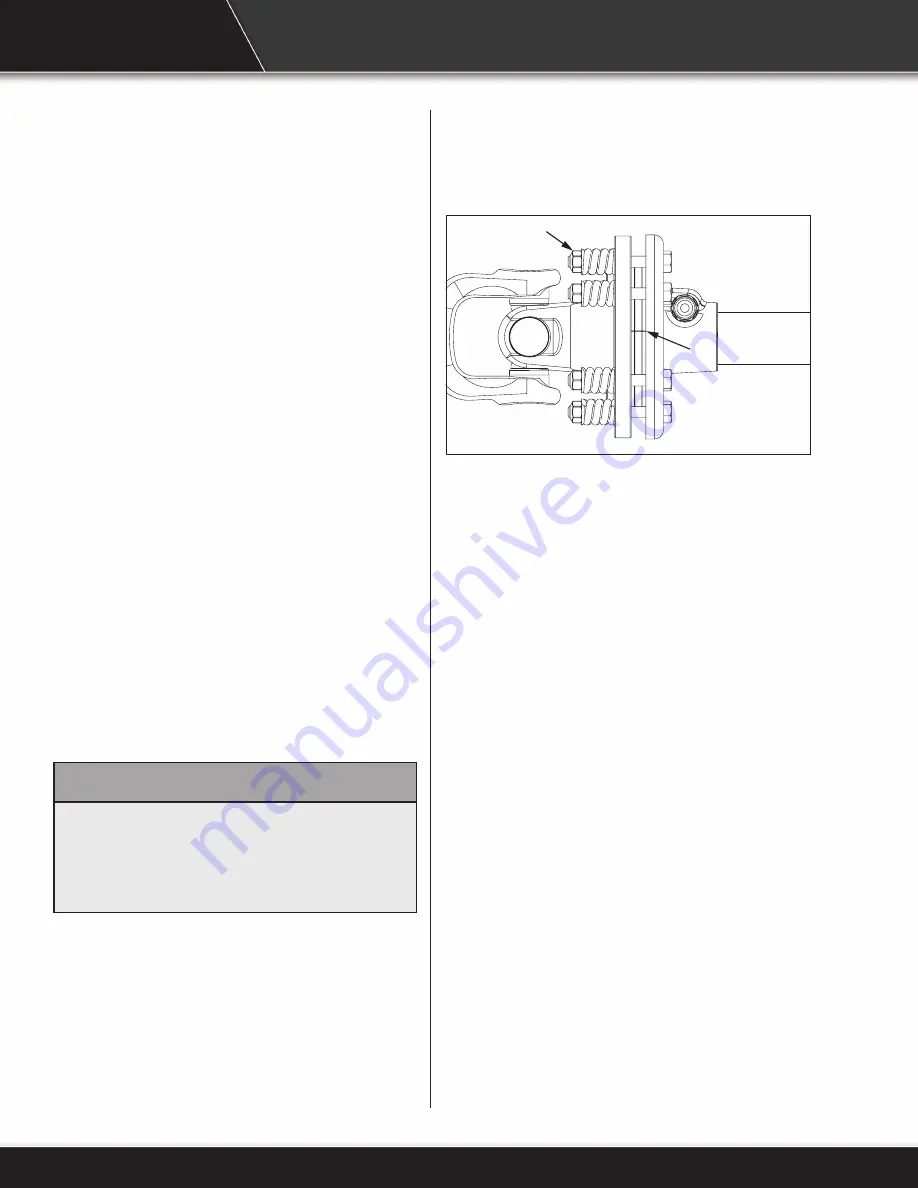

8.2.1 Slip Clutch

^

WARNING

Entanglement in a rotating driveshaft

can cause serious injury or death.

Disconnect and lockout power source

before adjusting or servicing.

1. Disengage tractor PTO. Shut off engine and

remove key.

2. Using a marker, scribe a line (A) across the

exposed edges of the clutch plate and friction

discs.

3. Loosen each compression nut (B) exactly two

revolutions to free clutch friction discs.

8.1 Storing Grinder

A

B

4. Start tractor and run driveshaft at a low idle to

slip the friction discs. This will remove the dirt,

corrosion and surface floss from clutch plate

faces.

5. Disengage tractor PTO. Shut off engine and

remove key.

6. Inspect the clutch and ensure that the scribed

markings on the disc and plates have changed

position. If any two marks are still aligned is

an indication that these discs have not slipped.

Repeat steps 4-5.

7. After ensuring all discs are free, tighten the

compression nuts (B) uniformly, exactly two

revolutions to resent the clutch to original

pressure.

32