6.4 Lubrication

^

WARNING

Prevent serious injury or death caused

by unexpected movement:

1�

Park on a level surface�

2�

Lower boom mower to ground�

3�

Engage parking brake�

4�

Shut off engine and remove key�

Pump grease into grease fittings located at all

pivot points and cylinder ends every month.

The rotor bearings are factory lubricated with a

lithium or lithium complex base grease which is

suitable for most applications. Select a grease

that is compatible with a lithium or lithium complex

grease.

The bearings should contain as much grease as

speed will permit. A full bearing with consequent

slight leakage through the seal is the best

protection against contaminant entry.

The following table is a general guide for normal

operating conditions. Extreme situations may

require a change in lubricating periods as dictated

by experience.

Generally, a lower quantity of grease at frequent

intervals is more effective than a greater quantity

at extended lubrication intervals.

Using the table below, the boom mowers operate

in the 1501-2000 rpm range. Determine the

lubrication interval based on the hours of use per

day. Typical lubrication quantity is 1 pump from a

standard grease gun.

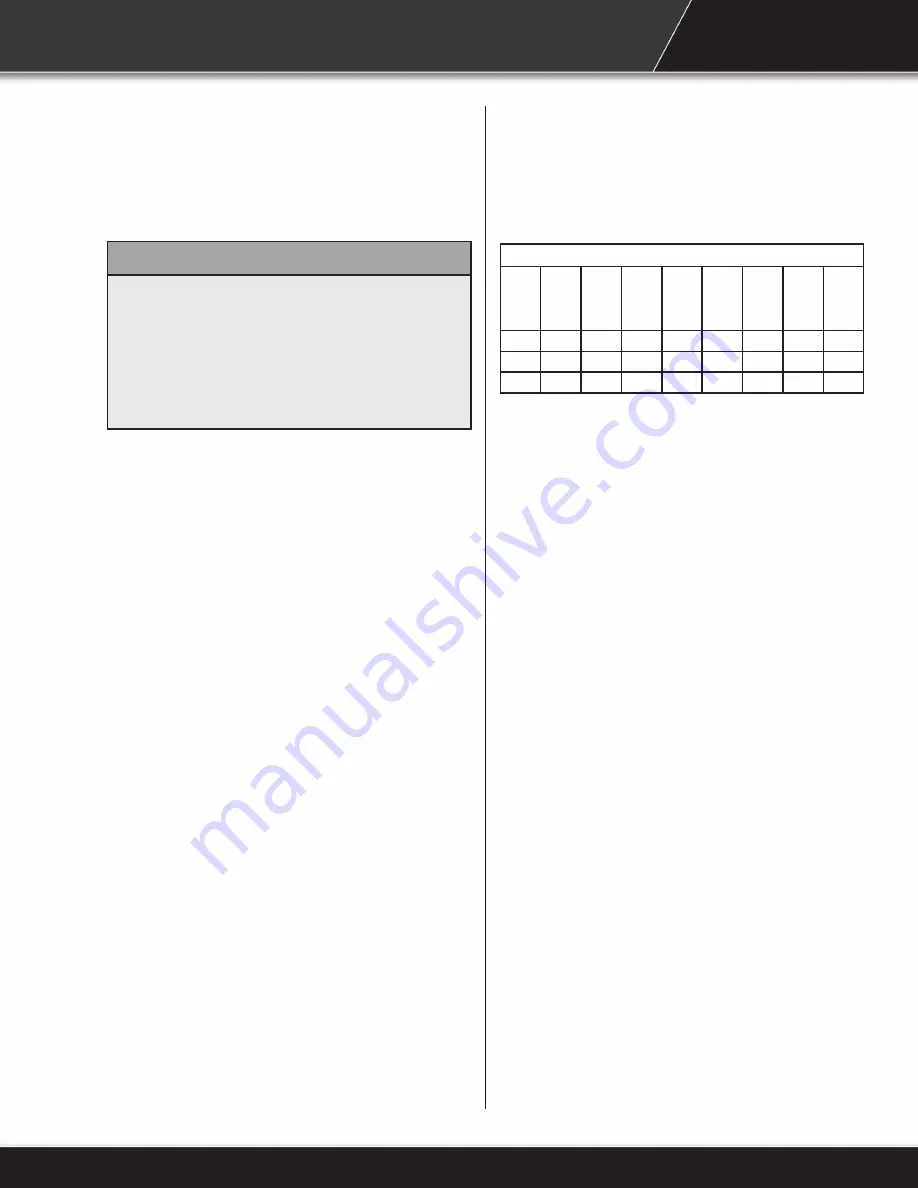

Lubrication Interval In Weeks

Hours

Run

Per

Day

1 To

250

RPM

251

To

500

RPM

501

To

750

RPM

751

To

1000

RPM

1001

To

1500

RPM

1501

To

2000

RPM

2001

To

2500

RPM

2501

To

3000

RPM

8

12

12

10

7

5

4

3

2

16

12

7

5

4

2

2

2

1

24

10

5

3

2

1

1

1

1

In the higher speed ranges too much grease will

cause overheating. The amount of grease that

the bearing will take for a particular high speed

application can be determined only by experience.

If excess grease in the bearing caused overheating,

it will be necessary to remove grease fitting to

permit excess grease to escape.

23