1. INTRODUCTION

Congratulations on your choice of a Baumalight

Stump Grinder to complement your stump grinding

operation. This equipment has been designed and

manufactured to meet the needs of a discriminating

buyer for efficient grinding of stumps.

Safe, efficient and trouble free operation of your

Stump Grinder requires that you and anyone

else who will be operating or maintaining the

Stump Grinder, read and understand the Safety,

Operation, Maintenance and Troubleshooting

information contained within the Operator’s

Manual.

This manual covers the Baumalight WB44 Stump

Grinder. Use the Table of Contents as a guide to

locate required information.

Keep this manual handy for frequent reference

and to pass on to new operators or owners. Call

your Baumalight dealer, distributor or the factory

if you need assistance, information or additional

copies of the manuals.

Modifications may compromise safe operation of

machine, subject users to serious injury or death and

may void any remaining warranty.

This operator’s manual does not replace, nor does its

use discharge the operator from observing all safety

codes or operating limitations as well as any applicable

federal, state, provincial or local regulations.

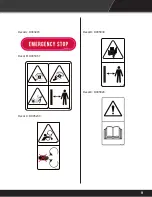

There are three different types of labeling on this

machine: safety, informative and product labels.

Safety Labels

are pictorial with a yellow

background and generally 2 panel. Top panel

indicates the potential hazard and the bottom

panel indicates how to avoid the hazard.

Informative Labels

are generally pictorial, have

a white background and can vary to the number

of panels. The label will illustrate the function

of a feature and is accompanied by detailed

1.1 Overview

The stump grinder is designed to be used by an

experienced operator. Operator must be trained

in the safe operation and hazards related to using

the stump grinder, and the safe use of the grinder

for the intended purpose. Operators will require

personal protective equipment to reduce the risk

from some hazards that cannot be completely

eliminated or controlled by the design of the

grinder.

Care is required to ensure that the stump grinder

will not come across metallic objects, stones or

other materials.

Stump grinders are not designed for use in

hazardous atmospheres where there is a risk

of fire or explosion due to flammable gases or

vapors. Use in hazardous, explosive atmospheres

is prohibited. Serious injury or death of the operator

or bystanders may be caused if grinder is misused.

1.2 Intended Use And Foreseeable

Misuse

instructions in the owners manual, with the label

illustrated along side.

Product Labels

contain product information such

as model number or serial number.

1