4. OPERATION

^

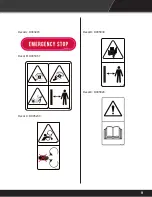

Keep bystanders, livestock, pets, etc away

from work area.

^

Always wear protective equipment appropriate

for the job.

^

Do not operate, work on or around this machine

while under the influence of alcohol, drugs or if

feeling ill.

^

Keep clear of moving machinery at all times.

^

Stop stump grinder engine before leaving

operators area.

^

It is your responsibility to operate this equipment

safely. You must be familiar with the equipment

and all safety practices before use.

^

Do not allow untrained or unqualified people to

operate this equipment.

4.1 Pre-Operation Check Lis

t

Perform the following checks prior to operation.

• Review and understand this manual and

engine operators manual.

• Verify safety decals are installed and legible.

Replace if damaged or missing.

• Verify that all hardware is tight.

• Verify that local utilities have marked all

underground utilities.

4.2 Carbide Teeth Break In

New carbide teeth are razor sharp and can chip and

shatter easily when they hit hard objects. Once the

razor sharpness has worn away, tips do not chip

as easily. Observing these precautions will extend

the life of the carbide teeth and reduce operating

expenses.

4.3 Operation

^

WARNING

Prevent serious injury or death.

Keep clear of moving components.

^

WARNING

Prevent serious injury or death.

Engine exhaust contains carbon

monoxide. Carbon monoxide is an

odorless gas that can cause death.

Avoid any areas or actions that expose

you or others to carbon monoxide.

^

WARNING

Wear an approved respirator (N95 Type

as a minimum).

Follow local, state and federal

regulations.

The health effects from exposure to

wood dust are due to chemicals in the

wood or chemical substances in the

wood created by bacteria, fungi, or

molds.

^

WARNING

Never operate stump grinder when other

people are in the vicinity. Debris can be

thrown several feet from cutting area.

Keep all shields in place.

10