5 SERVICE AND MAINTENANCE

^

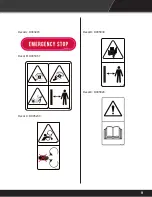

WARNING

Moving parts can crush and cut.

Keep clear of moving components.

Stop engine before performing

inspections or maintenance.

^

WARNING

Prevent serious injury or death.

Wear proper protective equipment

appropriate for the job.

5.2 Inspections

Inspect the unit for worn or damaged parts. Repair

or replace parts as needed.

5.1 Maintenance Intervals

Item

Daily

Before

Use

Every

4

Hours

Every

30

Hours

Weekly

Every

100

Hours

Verify emergency stop is functioning properly.

●

With engine stopped, verify throttle is fully open when

safety bar is pulled tight against handle.

●

Check cutting teeth for wear. Rotate or replace

cutting teeth as necessary.

●

Check engine air filter. Clean or replace as

necessary.

●

Lubricate pivot point grease fittings.

●

Lubricate rotor bearings

●

Check rotor bearings for side-to-side and up/down

movement. Replace bearings if movement is found.

●

Check drive belt condition and tension.

●

Change engine air filter.

●

Change engine oil.

●

5.3 Throttle Inspection

With engine stopped, pull safety bar tight against

handle and verify throttle (A) is against stop (B).

If throttle is not against stop, loosen clamp screw

(C) and adjust throttle cable case as necessary.

Tighten screw (C) and re-check. Throttle (A)

must be against stop (B) and when safety bar

is tight against handle. Engine must be running

at operating speed (3600 rpm) when grinding a

stump.

14