6

MAINTENANCE

Warning:

When repairing, maintaining and cleaning the machine, it is particularly important

to be aware of the safety precautions. Park the tractor (if connected) as a precautionary

measure and disconnect power when servicing. Do not clean, lubricate or adjust the machine

before the tractor engine has been stopped and the parking brake is activated.

Important:

Screws and bolts on your new machine must be tightened up after the first two

hours of operation. All moveable parts must be greased regularly for the best performance.

To extend the durability of the machine, frequent and thorough cleaning is recommended. Set

spring tension to loosest setting for ease of cleaning the machine and use plenty of water

when cleaning to avoid material freezing on the roller or rubber belts.

Remember:

Do not spray water directly into bearings or bearing housings. If the machine is

stored for a lengthy period of time, spray it with acid-free oil before use. Remove all foreign

material from the roller. Check and lubricate all chain and bearings regularly.

It is important to properly maintain and service your spreader. Failure to comply

with the manufacturer’s suggested servicing procedures m

ay result in premature

wear and may hinder the machine’s performance.

ATTACHMENT OF THE MACHINE

This spreader can be attached to the tractor using various methods. It is the operator’s

responsibility to make sure that it is connected and fastened properly and safely. Ensure that

the spreader sits horizontally when in operation.

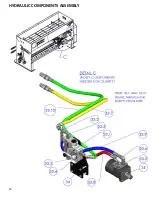

Hydraulic Units:

Ensure the hydraulic hoses are properly connected to the tractor’s hydraulic

ports. Improper connection may damage the machine if the oil runs in the wrong direction.

Flow control and hoses to the tractor are included.

Electric Units:

Ensure the wiring kit is properly connected to the tractor’s battery. A w

iring kit

is included. See page 15 for connection diagram.

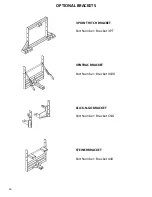

Mounting options include 3 Point Hitch bracket, Ventrac bracket, Click-N-Go bracket and

Steiner bracket. See page 16 for an illustration of these brackets.

Summary of Contents for 440E

Page 1: ...BAUMAN MANUFACTURING 440E 440H DROP SPREADER OPERATOR S MANUAL...

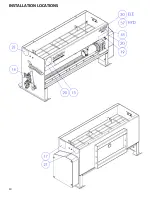

Page 12: ...10 INSTALLATION LOCATIONS...

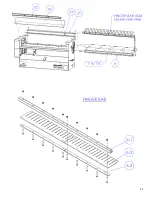

Page 13: ...11...

Page 14: ...12...

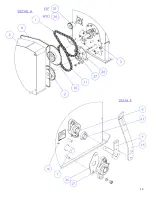

Page 15: ...13...

Page 16: ...14 HYDRAULIC COMPONENTS ASSEMBLY...

Page 17: ...15 ELECTRICAL HOOK UP DIAGRAM...

Page 21: ...19 NOTES...

Page 22: ...20...

Page 23: ...21...

Page 24: ...22...