9

440E, ELECTRIC SPECIFIC PARTS LIST

ITEM

#

PART NUMBER

DESCRIPTION

QTY.

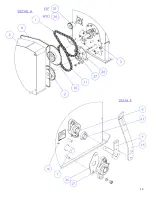

29

440 ELECTRIC DRIVE ASM

SEE COMPONENTS BELOW, COMES ASSEMBLED W/ HARDWARE

1

29.1

1801 440 MOTOR

1/4 HP 12VDC MOTOR

1

29.2

1801 440 REDUCER

REDUCER 35.5:1

1

30

DECAL 440E

MODEL # FOR 440E

1

31

40B12 010 EXT

#40-12 TOOTH 5/8" BORE-EXT

1

32

1801 440 ELE

ELECTRICAL TOGGLE KIT

1

32.1

1801 440 WIRE

WIRING HARNESS, FUSE, & QUICK-CONNECTS

1

32.2

1801 440 SWITCH

SWITCH BOX WITH LEAD

1

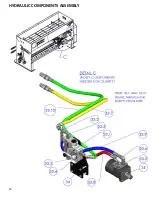

440H, HYDRAULIC SPECIFIC PARTS LIST

ITEM

#

PART NUMBER

DESCRIPTION

QTY.

33

HYD KIT 440H

HOSES AND FITTINGS FOR 440H

1

33.1

HYD FLOW

FLOW CONTROL VALVE 8GPM

1

33.2

HYD6602-6-6-6

SWIVEL NUT RUN TEE - MJIC x MJIC x FJIC

1

33.3

HYD6801-6-8

STRAIGHT THREAD ELBOW - MJIC x MORB 90°

2

33.4

HYD6400-6-8

STRAIGHT THREAD CONNECTOR - MJIC x MORB

1

33.5

HYD6400-6-10

STRAIGHT THREAD CONNECTOR - MJIC x MORB

1

33.6

HYD6801-6-10

STRAIGHT THREAD ELBOW - MJIC x MORB 90°

1

33.7

HYD440TH52

3/8 3000 PSI 1/2" NPT X 3/8 JIC 90 ELBOW

1

33.8

HYD440MH15

3/8 3000 PSI 3/8 JIC STRAIGHT X 3/8 JIC 90 ELBOW

1

33.9

HYD440MH18

3/8 3000 PSI 3/8 JIC STRAIGHT X 3/8 JIC STRAIGHT

1

33.10

HYD440TH66

TRACTOR HOSE 3/8" JIC 90 x 1/2" NPT

1

34

440 601

FLOW CONTROL MOUNTING BRACKET

1

35

HYD MOTOR 440

50cm^3/rev HYDRAULIC MOTOR

1

36

40B12 100 EXT

#40-12 TOOTH 1" BORE EXT. HUB

1

37

DECAL 440H

MODEL # FOR 440H

1

Summary of Contents for 440E

Page 1: ...BAUMAN MANUFACTURING 440E 440H DROP SPREADER OPERATOR S MANUAL...

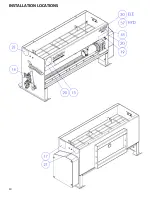

Page 12: ...10 INSTALLATION LOCATIONS...

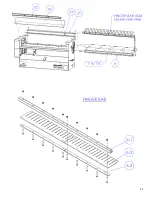

Page 13: ...11...

Page 14: ...12...

Page 15: ...13...

Page 16: ...14 HYDRAULIC COMPONENTS ASSEMBLY...

Page 17: ...15 ELECTRICAL HOOK UP DIAGRAM...

Page 21: ...19 NOTES...

Page 22: ...20...

Page 23: ...21...

Page 24: ...22...