Bäumr-AG Petrol Powered Lawn Mowers

E&OE

©2017 Bäumr-AG

3

General Fuel Safety

Petrol/fuel/gasoline is extremely

flammable – keep clear of

naked flames or other ignition

sources.

•

Do not spill fuel. If you spill fuel, wipe it

from equipment immediately – if fuel

gets on your clothing, change them

immediately

•

Do not smoke near fuel.

•

Always shut off the engine before

refuelling.

•

Do not refuel a hot engine.

•

Open the fuel cap carefully to allow any

pressure build-up in the tank to release

slowly.

•

Always refuel in well ventilated areas.

•

Always check for fuel leakage. If fuel

leakage is found, do not start or run the

engine until all leaks are fixed.

General Electrical Safety

•

Inspect electrical equipment, extension

cords, power bars, and electrical fittings

for damage or wear before each use.

Repair or replace damaged equipment

immediately.

•

Ensure all power sources conform to

equipment voltage requirements and are

disconnected before connecting or

disconnecting equipment.

•

When wiring electrically powered

equipment, follow all electrical and

safety codes.

•

Wherever possible, use a residual

current device (RCD).

•

Electrically grounded equipment must

have an approved cord and plug and be

connected to a grounded outlet.

•

Do not bypass the on/off switch and

operate equipment by connecting and

disconnecting the power cord.

•

Do not use equipment that has exposed

wiring, damaged switches, covers or

guards.

•

Do not use electrical equipment in wet

conditions or damp locations.

•

Do not use electrical cords to lift, move

or carry equipment.

•

Do not tie electrical cords in tight knots

and ensure electrical cords do not

present trip hazards.

General Service Information

•

Have the equipment serviced or repaired

at authorized service centers by

qualified personnel only.

•

Replacement parts must be original

equipment manufacturer (OEM) to help

ensure that equipment safety is

maintained.

•

Do not attempt any maintenance or

repair work not described in this

instruction manual.

•

After use, the equipment and

components may still be hot – allow the

equipment to cool and disconnect spark

plugs and/or electrical power sources

and/or batteries from it before making

adjustments, changing accessories or

performing repair or maintenance.

•

Do not make adjustments while the

equipment is running.

•

Perform all service related activities

under suitable conditions, such as a

workshop etc.

•

Replace worn, damaged or missing

warning/safety labels immediately.

•

Do not clean equipment with solvents,

flammable liquids or harsh abrasives.

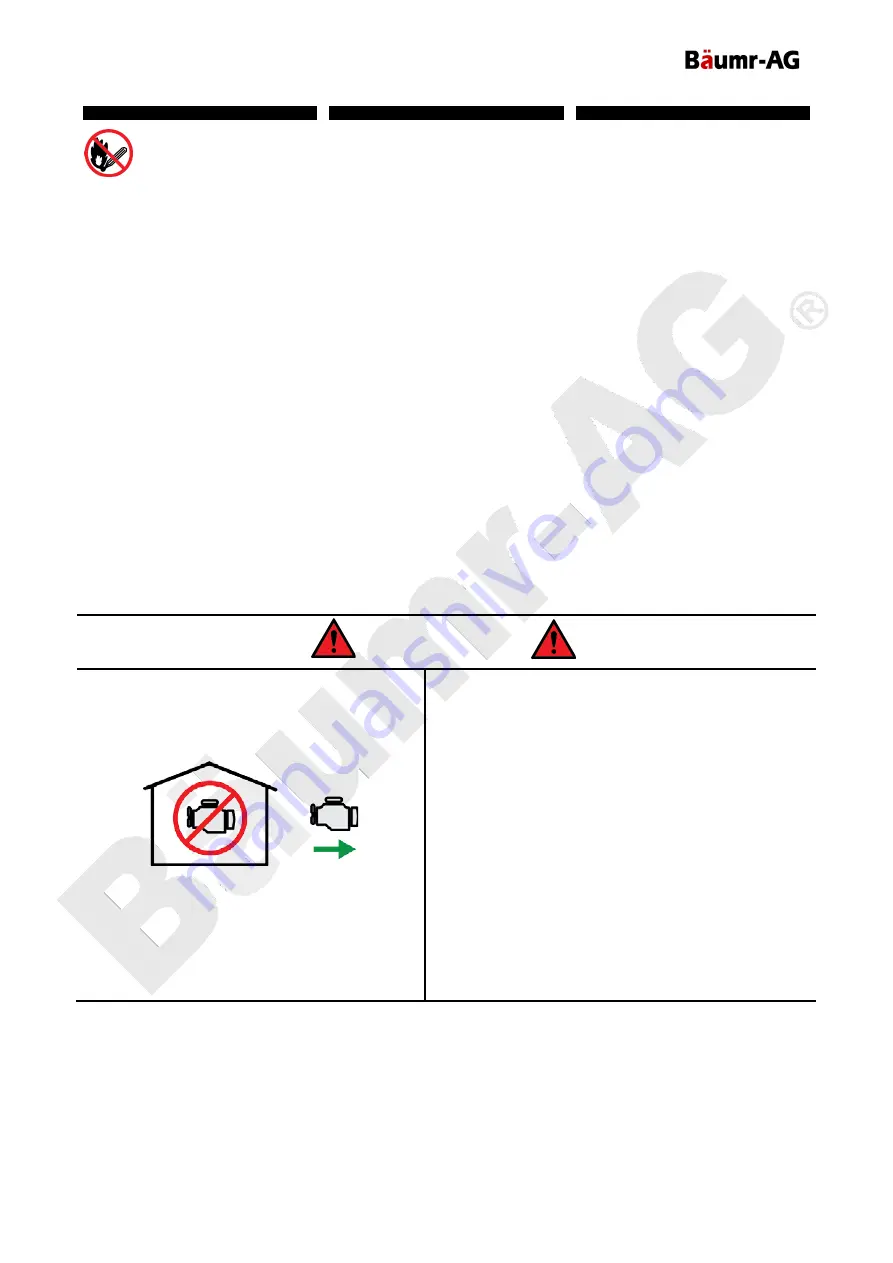

DANGER

Running combustion engines in confined areas

CAN KILL IN MINUTES. Engine exhaust fumes

contain carbon-monoxide – a deadly gas that you

cannot smell or see.

NEVER run a combustion engine in confined areas

EVEN IF windows and doors are open. ONLY run

petrol engines OUTDOORS and away from doors,

windows and vents.

Do not operate the equipment in hazardous locations,

such as where there may be a risk of fire or explosions

from flammable liquids, gases or dust.

Do not operate the equipment in confined areas where

exhaust gases, smoke or fumes could reach dangerous

concentrations.

Do not refuel a combustion engine while it is running, on

or hot.

Never smoke while refuelling combustion engines or

handling flammable substances.

For generators, the electrical output is potentially lethal

and must only be connected to a fixed electrical

installation by an appropriately licensed person.

Be aware that the equipment may include hazardous

components, such as blades, hot surfaces and moving

parts.

Handle any flammable substance with extreme caution.